Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-PCD-100JPayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

15 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

One year limited warranty with lifetime technical supportLab 100T 1500W Split Electric Isostatic Pressing Machine

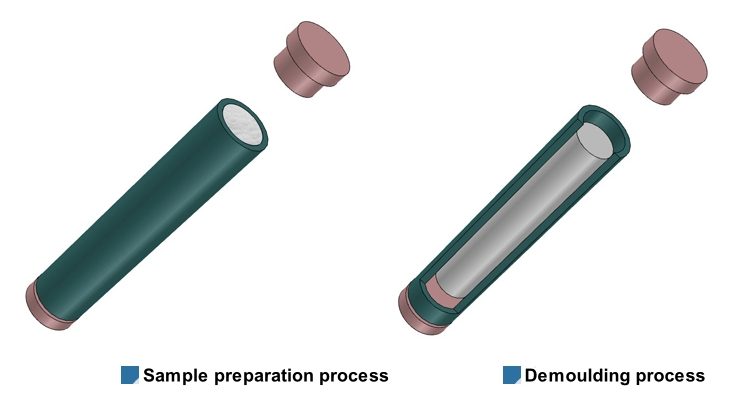

Mold diagram

Mold operation diagram

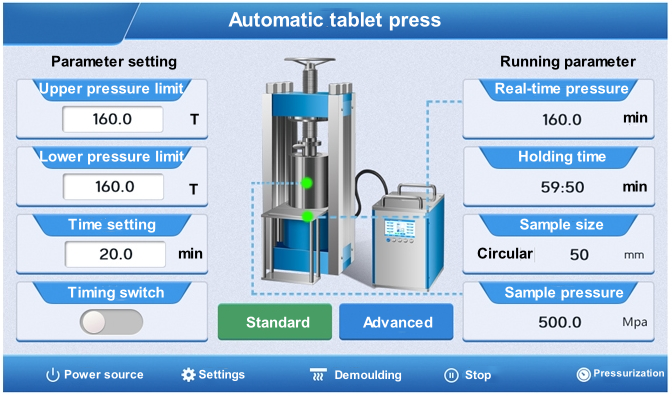

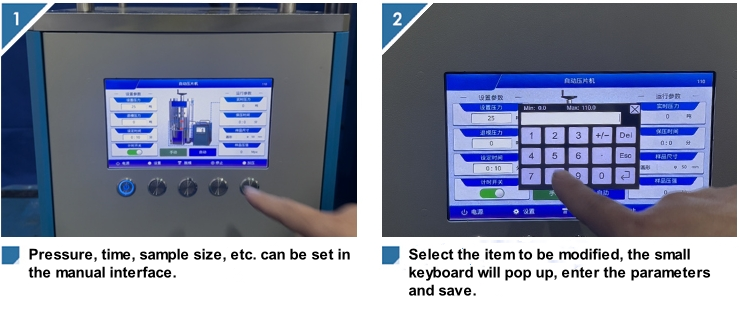

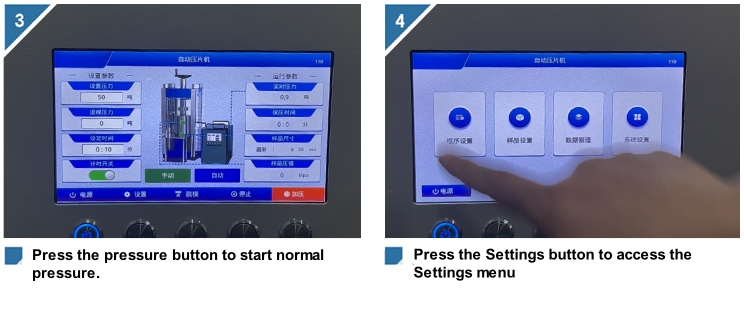

Operation interface (Manual mode)

Standard interface: Various parameters, pressure, demoulding, time, sample size, etc. can be set separately on this interface.

Pressurization button: Press according to the parameters set on the interface.

Stop button: Press the stop button during the pressurization process to stop the pressurization.

Demoulding button: Press the demoulding button to release the sample according to the demoulding pressure.

Timing switch: The timing function can be turned on and off.

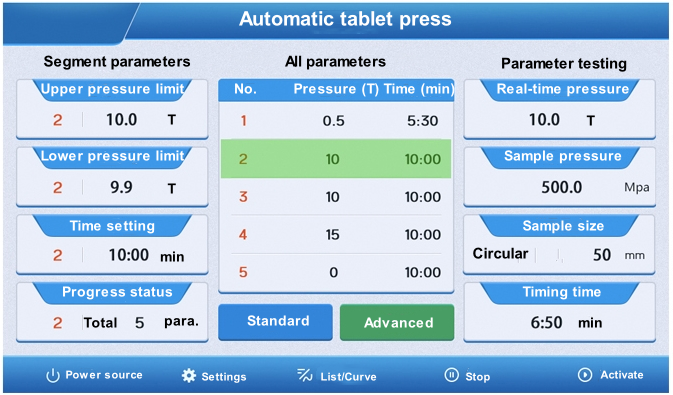

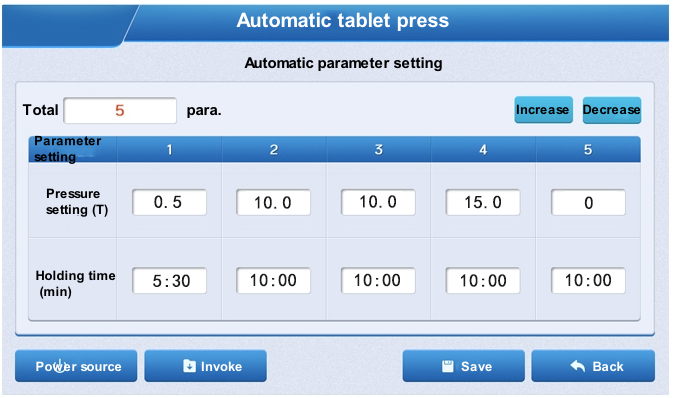

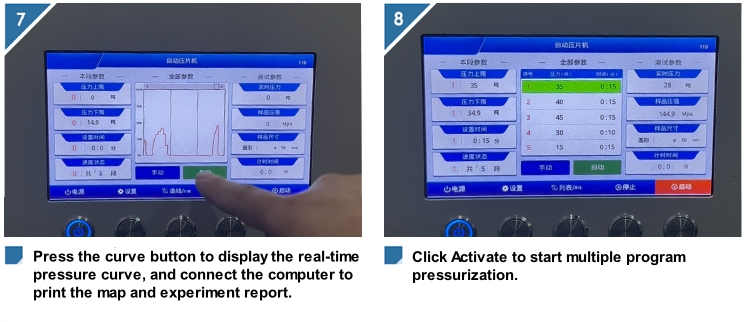

Operation interface (Automatic mode)

Activate button:It can be pressurized according to the multi-stage pressurization program.

Stop button: During the pressurization process, you can stop the pressurization process.

List/Curve: The current display state can be switched between list and curve

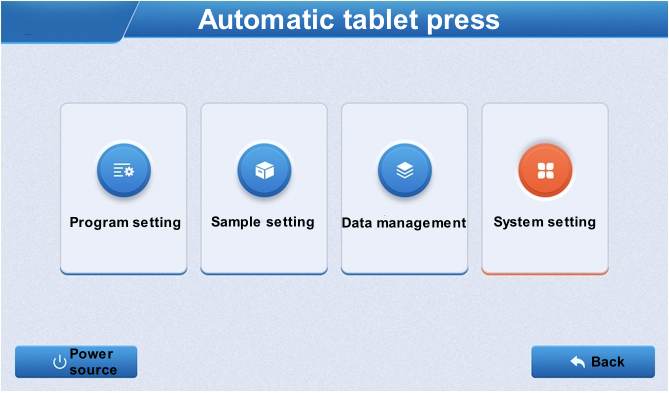

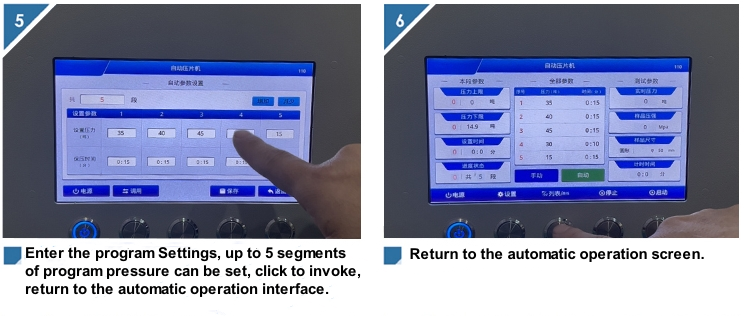

Setting interface

Tap Settings on the operation screen to enter the Settings screen. The Settings screen has four ICONS.

Program Settings:Multi-stage pressure procedures and pressure holding times can be set.

Sample setting: The shape and size of the sample can be set to facilitate the user to calculate the pressure of the sample.

Data management: Previously saved data records can be invoked and modified..

System Settings: Administrators can set various parameters, enter the password "666"

Setting interface

Multi-segment program Settings: Up to 5 segments of pressurized programs can be set.

Invoke button: Invoke the set parameters to the automatic operation interface for pressure.

Save button: Save the set parameters to the database for later invocation.

Back button: Returns to the Settings screen

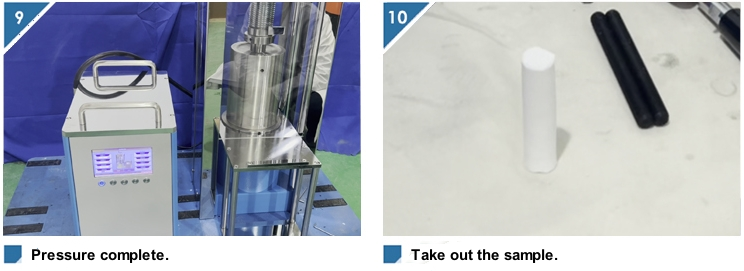

Operation procedure

Technical parameter

Instrument type

PCD-100J

Pressure range

0-100T

Piston diameter

Chrome plated cylinder Φ200mm(d)

Pressurization process

Programmed pressure - programmed pressure retention - timed pressure relief

Holding time

1 s to ∞ s

Pressure conversion

The program automatically converts the pressure of the sample

Liquid crystal display

7 inch LCD screen

Equipment protection

Steel plate protection with plexiglass doors

Isostatic pressure

0-300MPa

Isostatic pressure

φ60x150mm(MXN)0-300MPa

Isostatic pressure

φ50x150mm(MXN)0-500MPa

Space size

260x400mm(MXN)

Overall dimension

850X500X1100mm(LxWXH)

Equipment power supply

1500W(220V/110 can be customized)

Equipment weight

580kg

Powder tablet press size diagram

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

20T Lab Manual Cold Isostatic Press Hydraulic CIP Pressing MachineNext :

30T Small Volume Lab Electric Hydraulic PressCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported