Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-PC-600D2Payment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

15 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

One year limited warranty with lifetime technical support10T Integrated Manual Hot Press with 200X200mm Two Heating Flat Plates

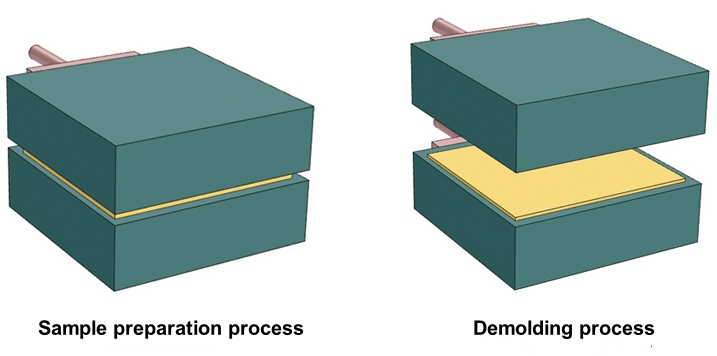

A: Mold operation diagram

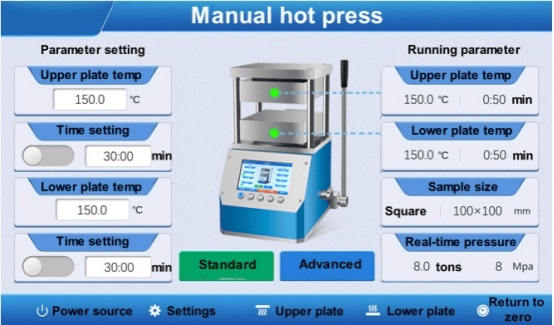

B: Operation interface (Standard mode)

Standard interface: The heating temperature and constant temperature time of the upper and lower plates can be set separately on the interface.

Return to zero button:Calibrate the pressure to zero.

Upper plate button: Heat the upper heating plate.

Lower plate button: Heat the lower heating plate.

Timing switch: The timing function can be turned on and off.

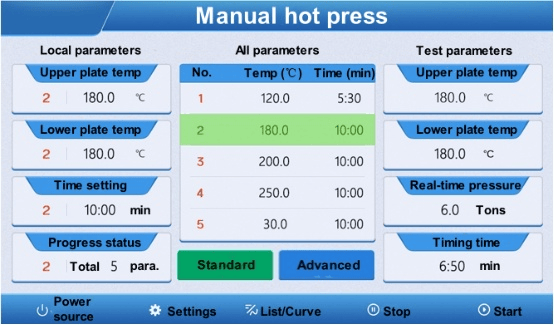

C: Operation interface (Automatic mode)

Start button: It can be pressurized according to the multi-stage pressurization program.

Stop button:During the heating process, pressing the stop button can stop the heating.

Setting button: Click the Settings button to enter the Settings menu.

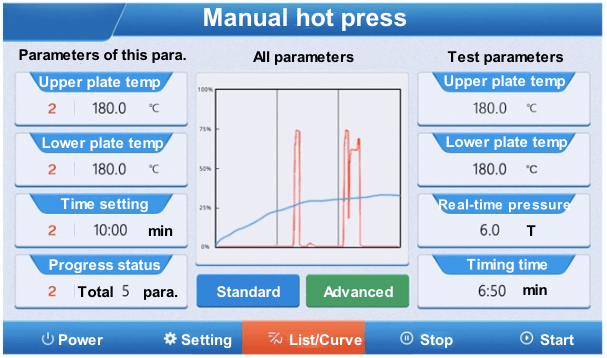

List/Curve: The current display state can be switched between list and curve.

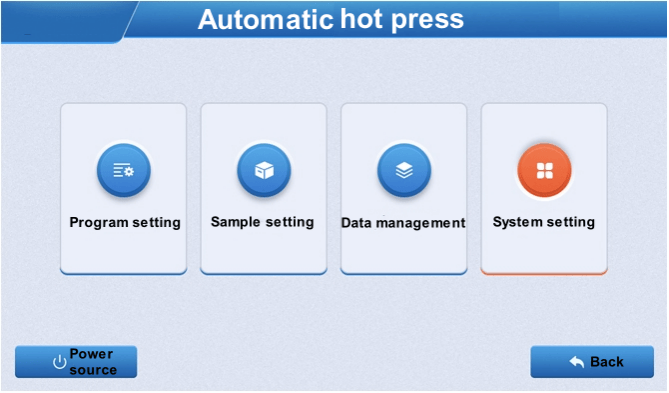

D: Setting interface

Tap Settings on the operation screen to enter the Settings screen. The Settings screen has four ICONS.

Program Settings:Multi-stage pressure procedures and pressure holding times can be set.

Sample setting: The shape and size of the sample can be set to facilitate the user to calculate the pressure of the sample.

Data management: Previously saved data records can be invoked and modified.

System Settings: Administrators can set various parameters, enter the password "666"

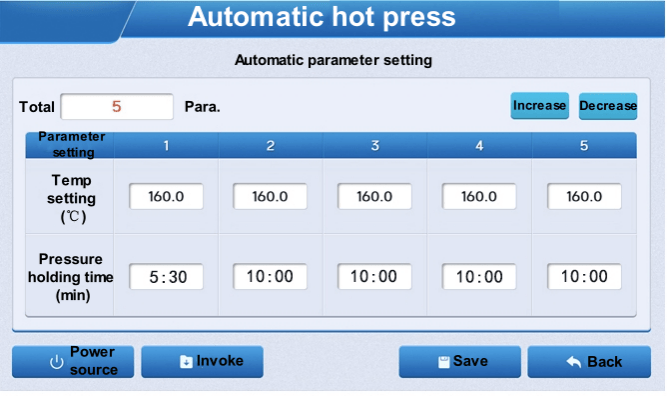

E: Setting interface

Multi-segment program Settings: Up to 5 segments of pressurized programs can be set.

Invoke button: Invoke the set parameters to the automatic operation interface for pressure.

Save button: Save the set parameters to the database for later invocation.

Back button: Returns to the Settings screen

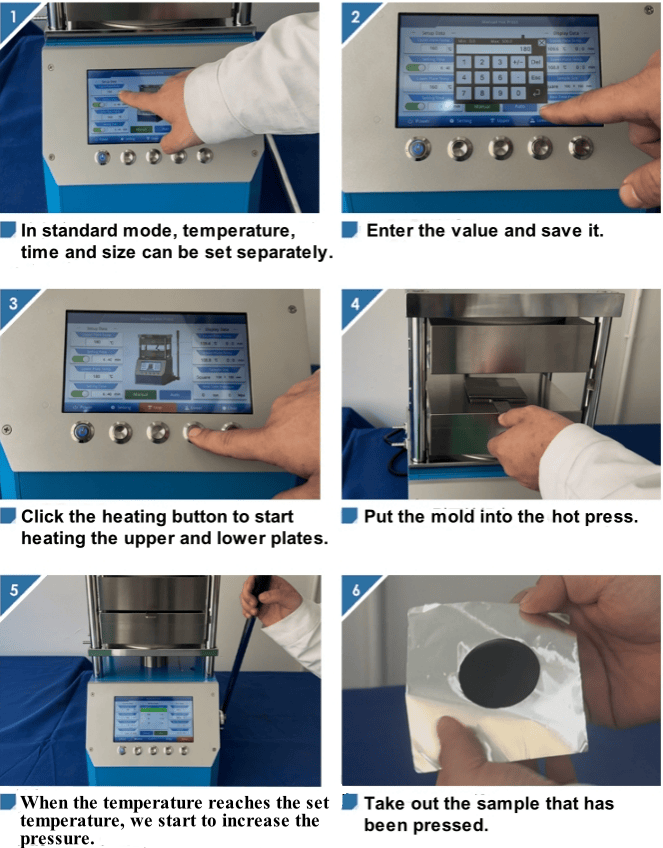

F: Operation procedure

G: Technical parameters

|

Instrument model |

TMAX-PC-600D2 |

||

|

Mold heating temperature |

Indoor temperature-300°℃ |

indoor temperature-500°℃ |

ndoor temperature-800°℃ |

|

Power |

2.5KW |

4KW |

5KW |

|

Pressure limit |

0-10.0 tons |

||

|

Pressure accuracy |

0.01 ton |

||

|

Piston diameter |

Chrome-plated cylinder Φ65mm(d) |

||

|

The overall structure of the main body |

The equipment has no sealed connection, reducing oil leakage points |

||

|

Constant temperature time |

1 second to ∞ seconds |

||

|

Temperature control accuracy |

0.1°C

|

||

|

Heat insulation method |

Imported heat insulation board |

||

|

Display screen |

7-inch touch screen |

||

|

Heating method |

Multi-stage heating or cooling programs |

||

|

Heat insulation method |

Imported heat insulation board |

||

|

Cooling method |

Water-cooled rapid cooling [Water-cooled machine selection] |

||

|

Power supply |

220V/110V can be customized |

||

|

Work space |

200×60mm

|

||

|

Mold size |

Double plate heating 200×200mm (M×N) |

||

|

Product size/weight |

320 × 290x 420 mm (L × W × H) / 95 kg

|

||

|

Packaging size/weight |

405 x330 × 550 mm (L X W X H) / 104 kg

|

||

|

Schematic diagram of the powder press machine dimensions |

|

||

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

300 X 300mm Double Flat Plate Heating Integrated Manual Hot PressNext :

300C Fully Automatic Hot Press Machine 500×500mm Flat PlateCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported