Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Item No.:

TMAX-SCK300Payment:

L/C, T/T, Western Union, Credit Cards, PaypalProduct origin:

ChinaShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

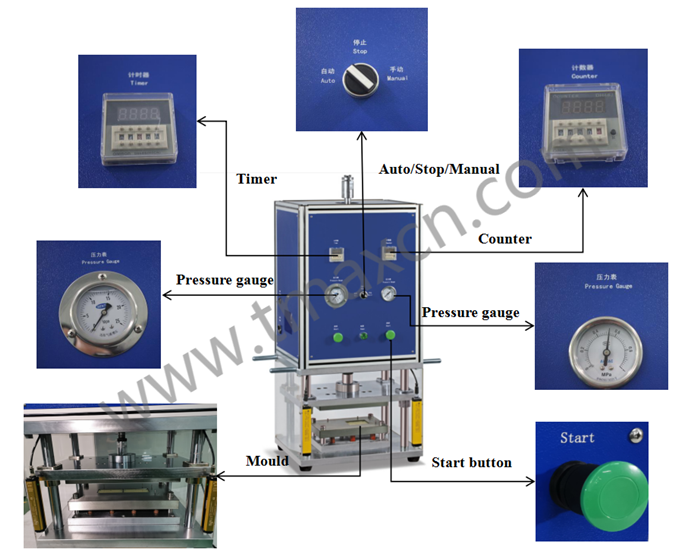

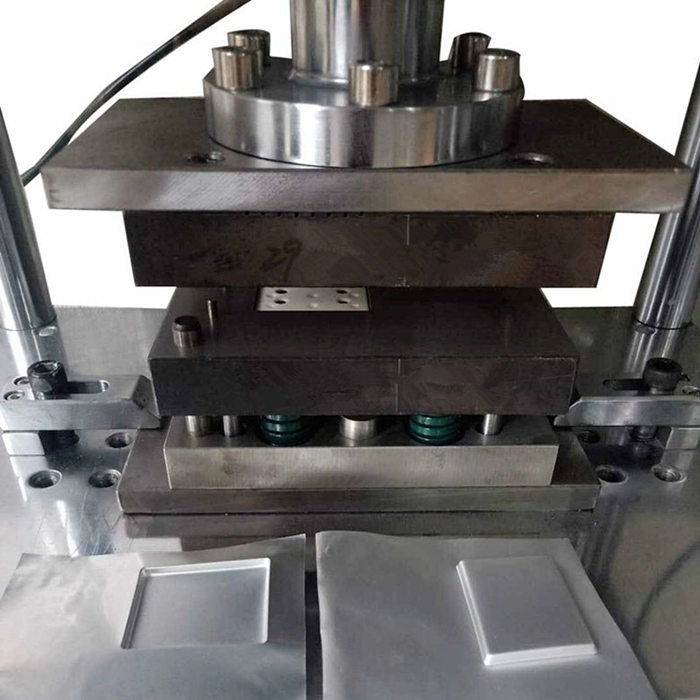

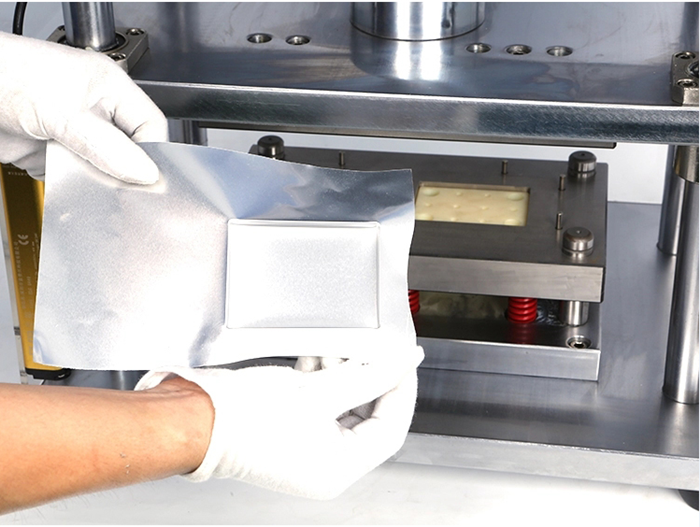

1 TMAX-SCK300 Battery Pouch Forming Machine is used for lithium polymer battery/ pouch cell cup forming in the production line of making pouch cell batteries.

2 The machine is used to prepare polymer cases made of Aluminum Laminated Films.

3 This lab aluminum laminated film pouch forming machine is designed with simple Spring mold with a smaller size, which is more suitable for lab research.

Main Feature:

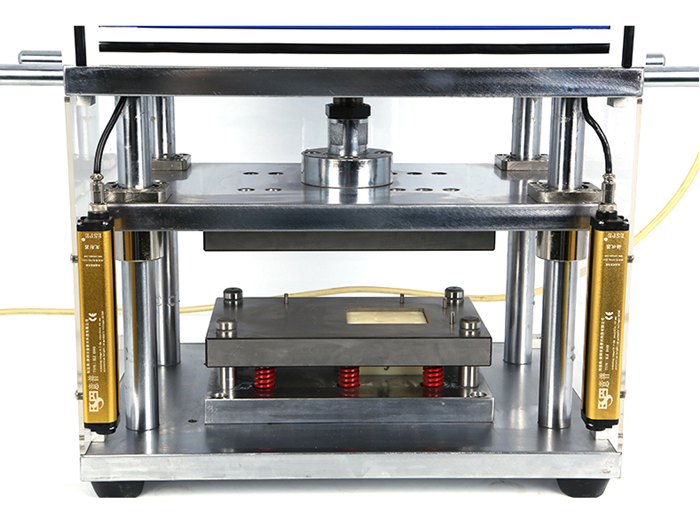

Four guide column structures for smooth sliding up and down.

It is simple and quick to change the mold and adjust the stretching depth..

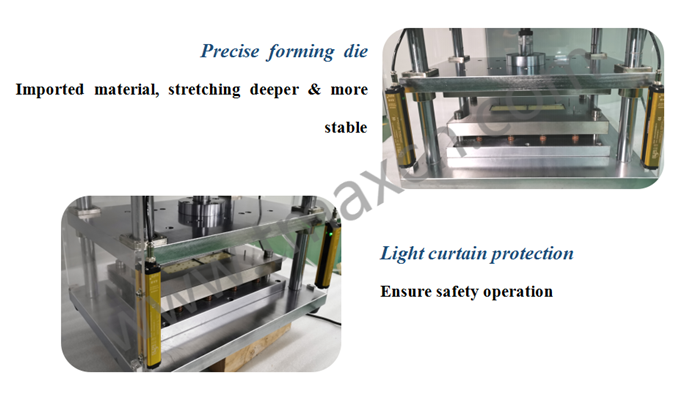

Compared with similar products, when use the same quality aluminum laminated film,this machine stretches deeper and more stable.

Precise mold design, no crow's feet and sag at each corner of the product after forming.

Protected by light curtain and cover, safe to use;

Made of Japanese imported mold material and high-strength chrome steel and alloy aluminum, the surface is treated with environmentally friendly plating and baking finish;

Exquisite appearance, sheet metal adopts three-dimensional geometric design, simple and beautiful.

Easy to operate, safe and reliable, small size

|

Model |

TMAX-SCK300 |

|

Source voltage |

AC 220V, 50HZ |

|

Power |

100W |

|

Warranty |

One year limited warranty with lifetime support |

|

Suitable aluminum film size |

300*280mm(L*W), customized, with punching depth ≤6mm |

|

Max. Cup Depth to Punch |

Single pit punching depth ≤6mm |

|

Output |

100-200EA/H |

|

Output pressure |

5T |

|

Air source |

0.5-0.7MPa |

|

Dimension(L*W*H) |

560*420*925mm |

|

Weight |

About 250 kg |

|

Mold part |

Mold/core roughness: :0.4(mirror reflection) Upper and lower die flatness: 0.02mm Core flatness: 0.02mm |

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Categories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported