Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-PCH-GPayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

15 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

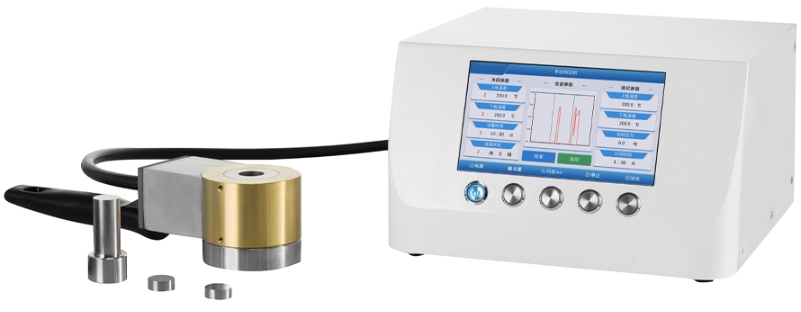

One year limited warranty with lifetime technical supportLaboratory 500C High Temperature Electric Heat Cylindrical Grinding Mold

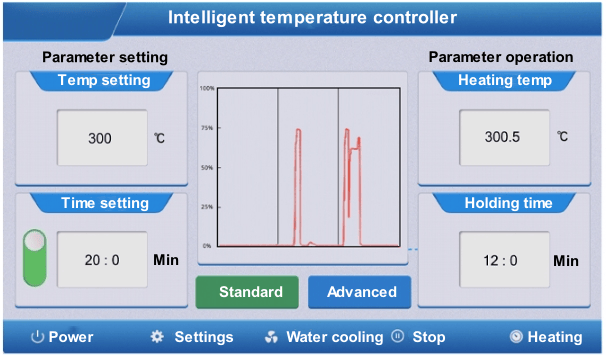

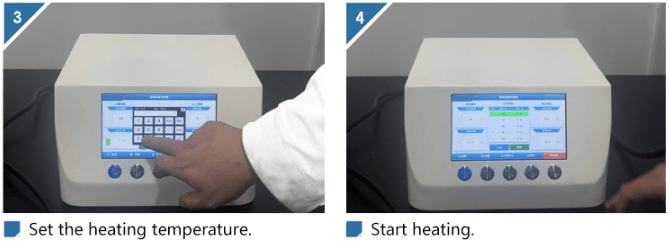

Operation interface (Standard mode)

Standard interface: The heating temperature and constant temperature time of the mold can be set separately on this interface.

Water-cooling button: The power supply of the water-cooling machine is connected to the thermostat, which can control the on and off of the water-cooling machine.

Heating button: Click this button and the mold will start heating.

Stop button: Click this button and the mold will stop heating.

Timing switch: Used to turn the timing function on and off.

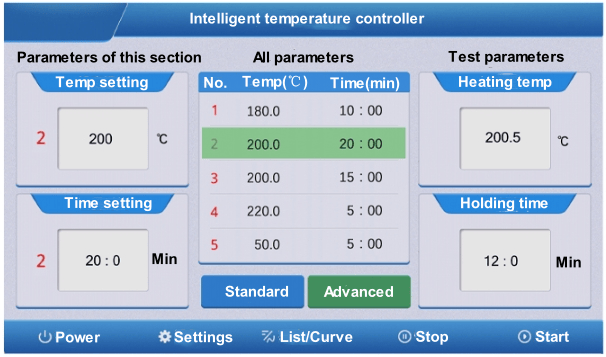

Operation interface (Advanced mode)

Start button: In the advanced mode, by clicking the start button, the hydraulic press can be heated up according to the multi-stage heating program.

Stop button: During the heating process, clicking the stop button can stop the heating.

List curve: Current display status. The list and curve graph can be switched.

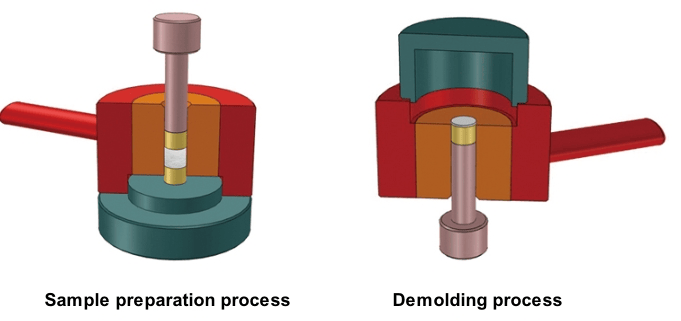

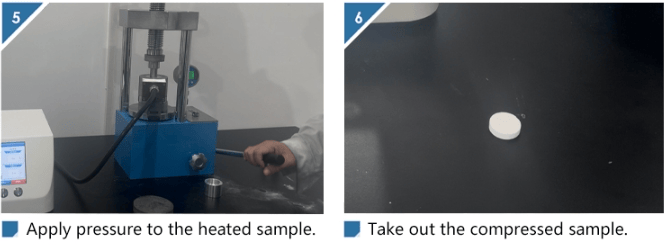

Schematic diagram of mold operation

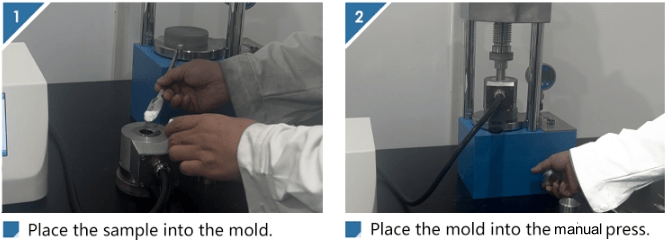

Operation steps

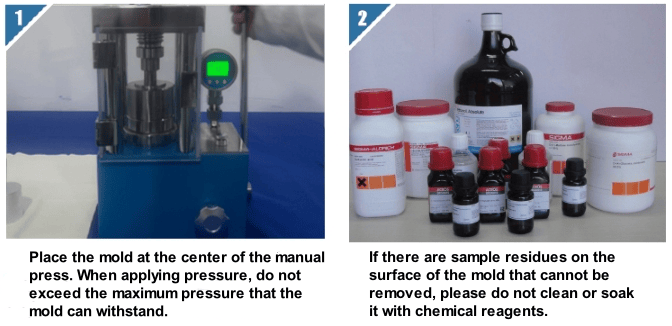

Mold usage and maintenance

Each time the mold is used, the surface of the mold should be wiped clean with lint-free paper first to prevent the anti-rust oil on the mold from affecting the test results of the sample. When applying pressure, it is necessary to pay attention not to exceed the maximum pressure that the mold can withstand. After using the mold, the samples on the mold should be cleaned in time to prevent corrosion of the mold. When the mold is not used for a long time, anti-rust oil should be applied to the mold and it should be stored in a dry environment.

Technical parameters

|

Instrument model |

PCH-G |

|

Pressed sample shape |

|

|

Heating temperature |

Room temperature - 500.0℃ |

|

Mold material |

Alloy tool steel :440C |

|

Indenter hardness |

HRC60-HRC62 |

|

Sample size |

φ10, φ13, φ15, φ20, φ30, φ40mm(M) |

|

Cavity depth |

40mm(N) |

|

External dimensions |

φ78x138mm, φ90x138mm(LXH |

|

Power supply power |

500W(220V/110V, customizable) |

|

Mold weight |

About 10 kg |

|

Schematic diagram of dimensions |

|

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Laboratory Automatic Laminating Heat Press Flat Hot Press MachineNext :

30T 500C Double Plate Vacuum Integrated Hot Pressing MachineCategories

© Copyright: 2025 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported