Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-PP-150SPayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

15 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

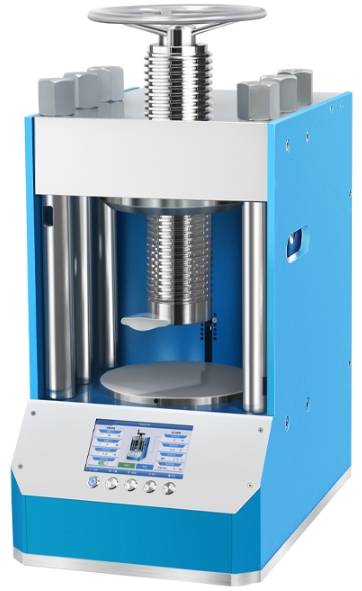

One year limited warranty with lifetime technical supportLab 150T Large Tonnage Automatic Programmable Powder Press Optional Computer for Remote Control

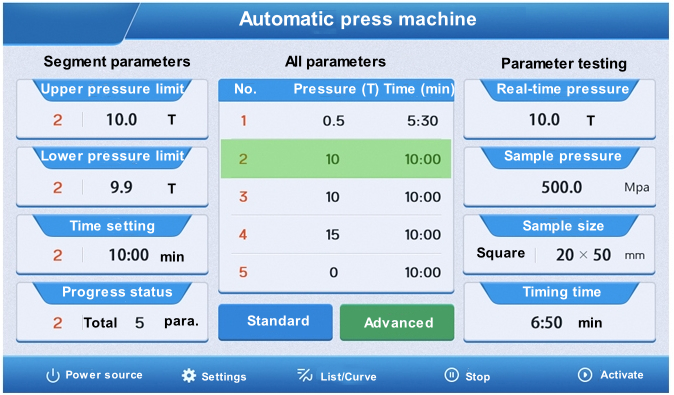

Operation interface (Standard mode)

Standard interface: Various parameters can be set in this interface individually: pressure, demoulding, time, sample size, etc

Pressurization button: Press according to the parameters set on the interface.

Stop button: Press the stop button during the pressurization process to stop the pressurization.

Demoulding button: Press the demoulding button to release the sample according to the demoulding pressure.

Timing switch: The timing function can be turned on and off.

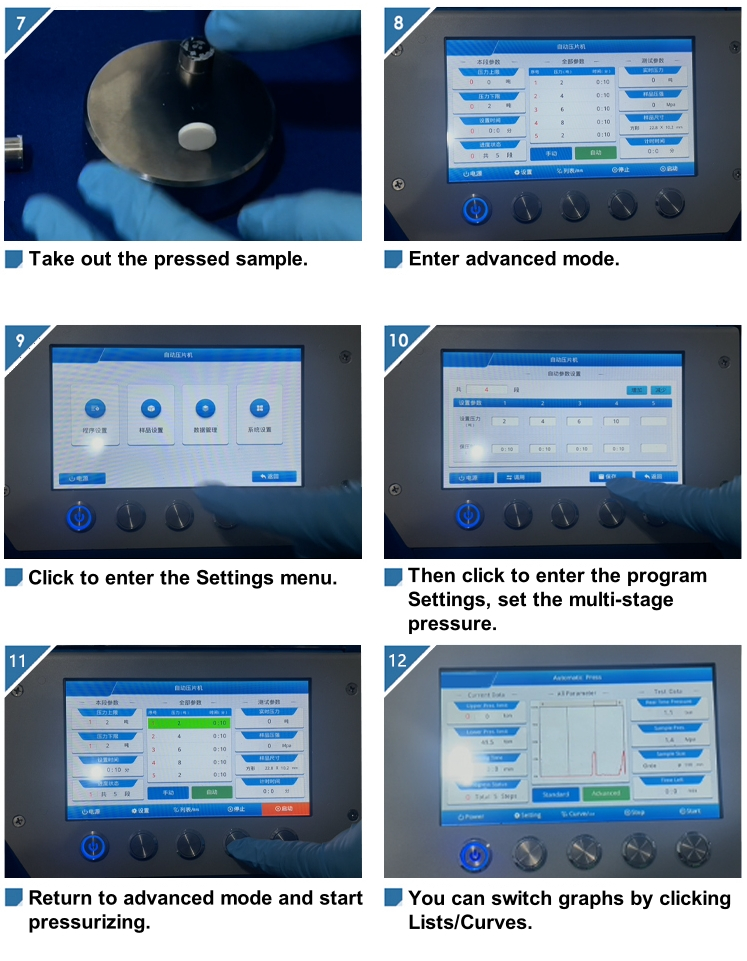

Operation interface (Advanced mode)

Activate button: Can be pressed according to the multi-stage pressurization program.

Stop button: During the pressurization process, you can stop the pressurization process.

Setting button: Click the Settings button to enter the Settings menu.

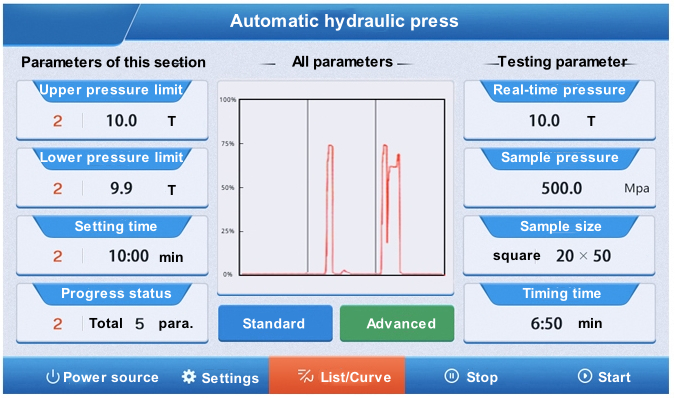

Operation interface (Advanced mode)

List/Curve: The current display state can be switched between list and curve.

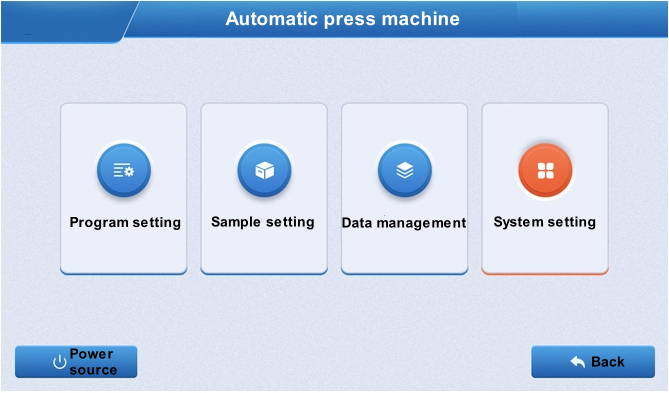

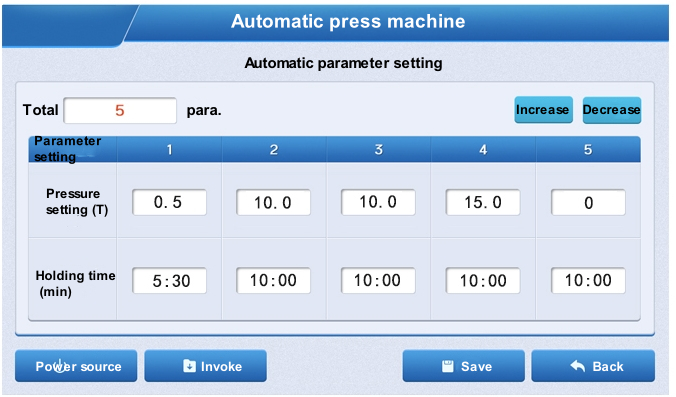

Setting interface

Tap Settings on the operation screen to enter the Settings screen. The Settings screen has four ICONS.

Program Settings: Multi-stage pressure program and pressure holding time can be set.

Sample settings: The shape and size of the sample can be set to facilitate the user to calculate the pressure of the sample.

Data management: Previously saved data records can be invoked and modified..

System Settings: Administrators can set various parameters, enter the password "666"

Setting interface

Multi-segment program Settings: Up to 5 segments of pressurized programs can be set.

Invoke button: Call the set parameters to the automatic operation interface for pressure.

Save button: Save the set parameters to the database for later invocation.

Back button: Returns to the Settings screen

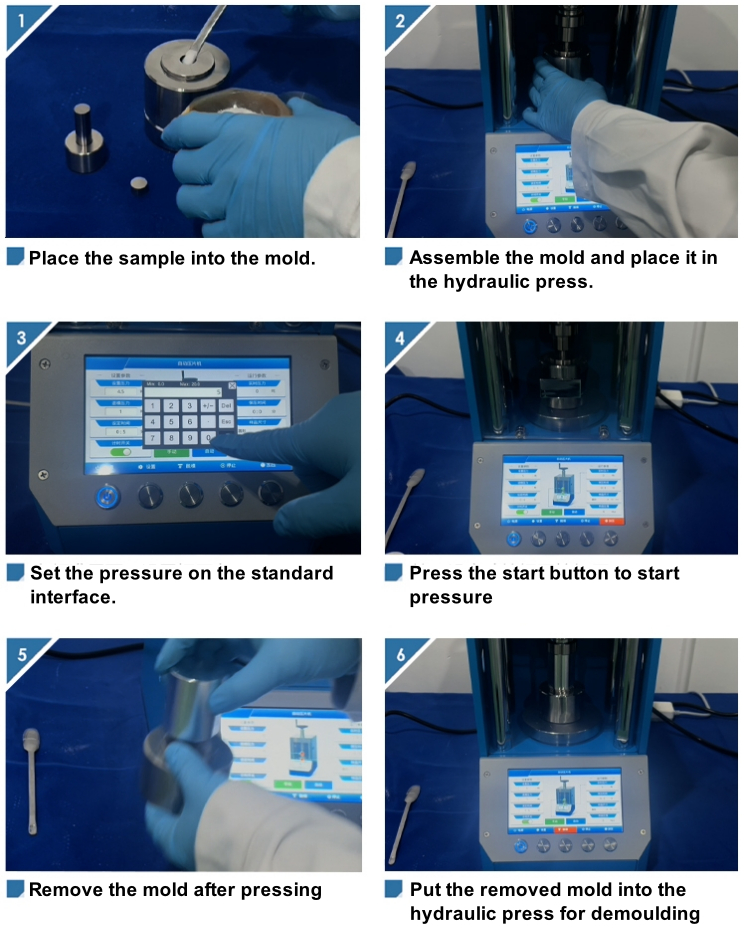

Operation procedure

Technical parameter

|

Instrument type |

PP-150S |

|

Pressure range |

0-150.0 tons |

|

Pressurization process |

20-segment programmed pressurization; pressure mapping can be displayed |

|

Holding time |

Each section lasts up to 32,768 seconds and can also work for a long time without timing |

|

Pressure conversion |

Automatically calculate the pressure endured by the sample based on its shape and size |

|

Pressure display accuracy |

0.1 ton |

|

Liquid crystal display |

7 inches (IPS HD) touch screen |

|

Metal keying |

Silver-plated contact, service life > 100,000 times |

|

Equipment protection |

Steel plate protection with plexiglass doors |

|

Limit switch |

Automatic pressure relief when the cylinder reaches the limit height |

|

Data analysis |

It can be optionally connected to a computer to achieve functions such as data recording, analysis, comparison, modification and export |

|

Pressure safety |

The equipment is equipped with automatic pressure overload protection |

|

Cylinder stroke |

50mm(T) |

|

Space size |

200x260mm(MXN) |

|

Overall dimension |

400X620X620mm(LxWXH) |

|

Equipment power supply |

1500W(220V/110 can be customized) |

|

Product size/weight |

400x620x620mm(LXWXH)/380 kg |

|

Packaging size/weight |

725x620x890mm(LxWXH)/416 kg |

|

Powder press size diagram |

|

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

1000C 5T Manual High Temperature Hot Press with Programmable 20-segment ProgramNext :

Lab 15T 500C High Temperature Manual Vacuum Hot Press with 300×300mm Heating PlateCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported