Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-1200-1200-1200tPayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

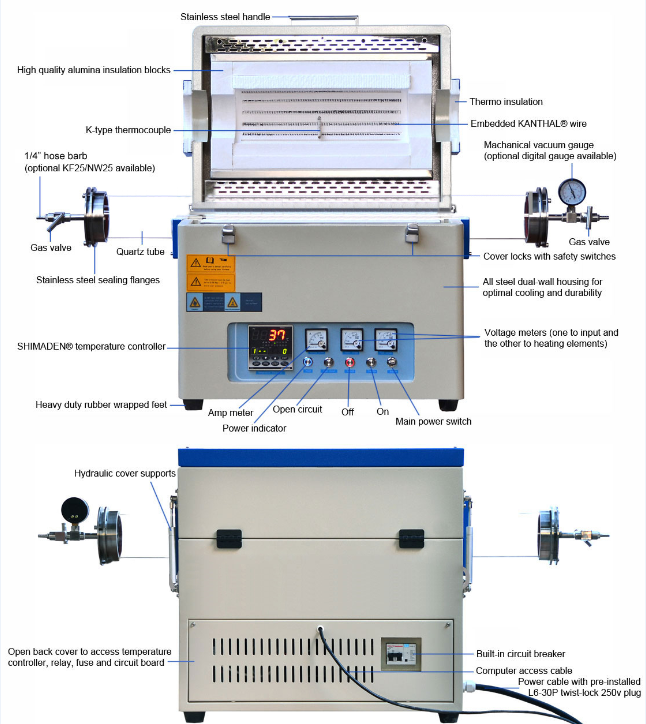

Two years limited warranty with lifetime technical supportLab 1200-1200-1200C Three Zone Tube Furnace for Atmosphere Sintering

This split tube furnace uses a resistance wire as a heating element, a double-shell structure and a 30-stage program temperature control system, phase shift triggering, thyristor control, and alumina polycrystalline fiber material for the furnace. It has the advantages of temperature field balance, low surface temperature, fast temperature rise and fall, energy saving, etc. It is an ideal product for high temperature atmosphere sintering, atmosphere reduction, CVD experiment and vacuum annealing in universities, research institutes and industrial and mining enterprises.

Detailed technical parameters

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Lab 1200C Mini Vertical Tube FurnaceNext :

Lab 1200-1200C Double Zone Tube Furnace for Atmosphere SinteringCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported