Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-SX2-V-12TPPayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

1200C Vertical Annealing Tube Furnace with Quartz Tube

|

Main parameter |

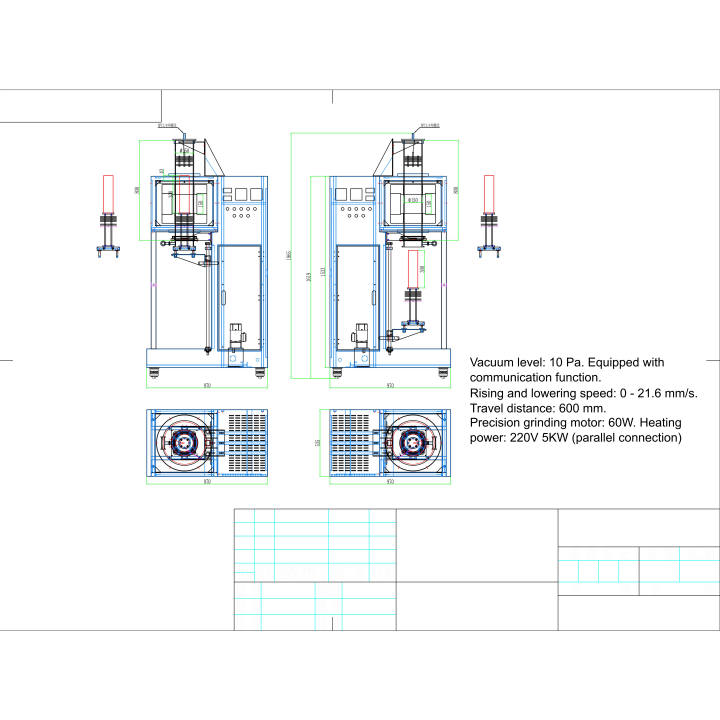

PN: SX2-V-12TP Max.design Temp: 1200C Working temperature:0-1100C Tube outer diameter:150mm The heating zone length:150mm Tube material:Quartz tube Voltage:220V,single phase 50HZ Power:5kw Heating rate:0~20 Degree/Min Max.vacuum: 10pa(cold state) Heating element:Resistance wire Thermocouple:K type Temperature accuracy: ±1℃ |

||

|

Sample loading |

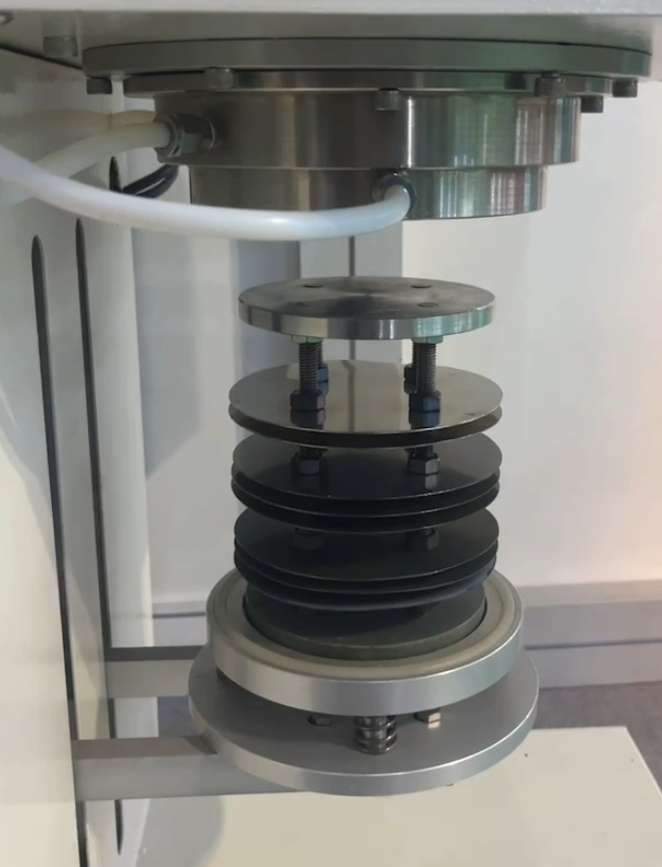

The top material tray is electrically adjustable, making it convenient to place and retrieve materials, The pallet is made of copper and features a lifting mechanism with an RS485 interface. |

||

|

Special requirements |

Top air intake, bottom air extraction; the bottom of the heated zone should be flush with the bottom of the workpiece; the workpiece height should be 5cm higher than the top insulation layer; the lifting stroke should be greater than the workpiece height. Electrical components meet CE standards, and power cords meet EU standards. |

||

|

Inlet gas/Atmosphere |

It can be filled with various protective or destructive gases,Inert gases, mixed gases, nitrogen, oxygen, etc |

||

|

Gas control |

The air inlet can be set up 1 air intakes, each air inlet is provided with a ball valve, connected with a pressure gauge. The air outlet is connected with vacuum pump, and all holes are equipped with ball valves. The maximum positive pressure in the tube does not exceed 0.02Mpa |

||

|

Furnace Chamber material |

Adopt the advanced light alumina ceramic fiber, with excellent thermal insulation effect, light weight, high temperature resistance, The energy saving effect is 60-80% of the old electric furnace. |

||

|

Furnace shell structure |

Electric furnace shell adopts double layer forced air cooling structure, so that the electric furnace works at the highest temperature and the external temperature of the shell is close to room temperature, so as to avoid accidental injury. |

||

|

Sealing way |

Adopt 304 stainless steel cooling flange, with easy loading and unloading, oxidation resistance, acid and alkali resistance, double seal, ensure the sealing |

||

|

Temperature control |

Adopt international advanced touch screen temperature controller, with 30 programmable PID self-tuning, automatic temperature rise, automatic temperature drop, no duty.With RS485 port |

||

|

Vacuum system |

Vacuum pump: Two-stage rotary vane pump Vacuum pump ultimate vacuum:10-1Pa Furnace vacuum:10Pa Single-channel vacuum gauge(with RS485) KF25 quick connect, vacuum bellows, vacuum gauge ect |

||

|

Warranty |

One year limited warranty with lifetime support, excluding heating element,cooling fans,thermocouple and quartz tube damaged by user. Attention: Any damages caused by the use of corrosive and acidic gases, and any damage from wrong operate and use are not under the coverage of One Year Limited Warranty. |

||

|

Standard Package Accessories: |

|||

|

Electric Furnace |

1 set |

|

|

|

High temperature gloves |

1 pair |

|

|

|

Crucible tongs |

1 pc |

|

|

|

Quartz tube |

1 pcs |

|

|

|

Stainless steel flange |

1 set |

|

|

|

Sample Material Rack |

1 set |

|

|

|

10mm Air pipe |

1piece |

|

|

|

User manual |

1 book |

|

|

|

Vacuum pump |

1 set |

|

|

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

1200Type Vacuum Quartz Tube Furnace with 350mm Tube Heating ZoneNext :

Lab 1200C 60mm Quartz Tube Furnace with Temperature ControlCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported