Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Item No.:

TMAX-MRX300Payment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

Automatic Battery Electrode Coating Machine For Lithium Battery Manufacturing

Introduction

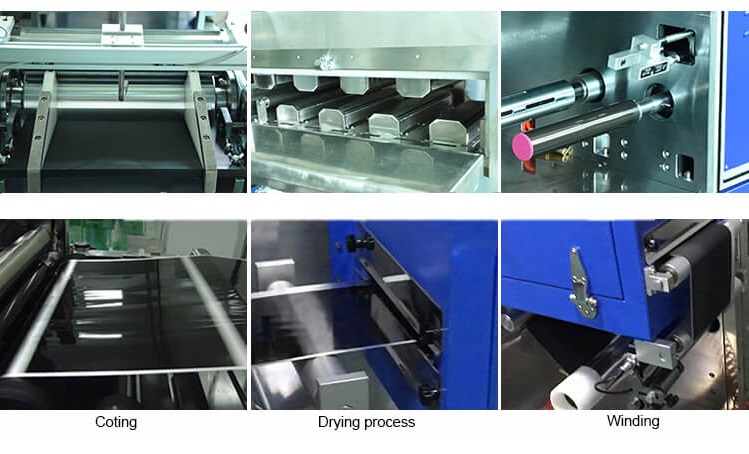

TMAX-MRX300 is a automatic battery electrode coating machine with a compact footprint that is less than 6'x3'. It uses transfer coating technique for better coating uniformity and is perfect for research or building prototypes (e.g. pilot scale studies) of new generation rechargeable batteries. It is integrated with the functions/ features of metallic foil roll unwinding (reeling out), slurry feeder, coating blade, baking oven, and final electrode winding (reeling in) together with touch screen operation for customer's the most convenience. Our company manufactures various types of Li ion battery equipment. We welcome your contacts from any place of world.

Specification

|

Working Voltage |

380V AC |

|

Max. Power Consumption |

10 KW ( 30A Air breaker required ) |

|

Max. Coating Width |

300mm |

|

Thickness adjustable range |

0-5mm |

|

Coating thickness (after drying) |

20 - 200um (for most kinds of battery electrode coating material) |

|

Thickness Precision |

± 3µm (± 5µm at edges) |

|

Coating Speed |

0-300 mm / minute |

|

Max. Drying Temperature |

150°C |

|

Temperature Accuracy |

±2.5°C |

|

Heating Zone Length |

710mm (28") |

|

Reeling/Unreeling Shaft |

75mm (ID) |

|

Max. Reeling/Unreeling Diameter |

300mm (OD) |

|

Max. Coating Length |

Depending on the coating and substrate thickness.

Typically, 10um thick foil with 100um coating can get 600 meters of electrode length coated per run |

|

Coating Modes |

Using transfer coating technique ( Reverse comma ) for better uniformity

Two available coating modes selectable on the control panel.

Continuous mode

Intermittent coating ( system performs coating, stops, coats again and so on. The length of the coating and break

segments can be specified by the user ). |

|

Slurry Stirring |

SS316 Moving Rod |

|

Exhaust Port Size |

127mm O.D |

|

Compressed Air |

0.5-0.8 MPa (Air compressor not included. Please click here to order) |

|

Product Dimensions |

1650mm ( L) x 1250mm (W) x 1200mm (H) |

|

Warranty |

Two Years limited warranty with lifetime support

Rusting and damage due to improper storage condition or maintenance are not covered by warranty |

|

Net Weight |

1000 kg |

|

Shipping Dimension |

70" x 50" x 60" |

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Semi-Auto Pouch Cell Stacking Machine Lithium Ion Battery Electrode StackerNext :

Lithium Battery Separator Soaking And Coating EquipmentCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported