Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Item No.:

TMAX-Vertical-Plate3Payment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

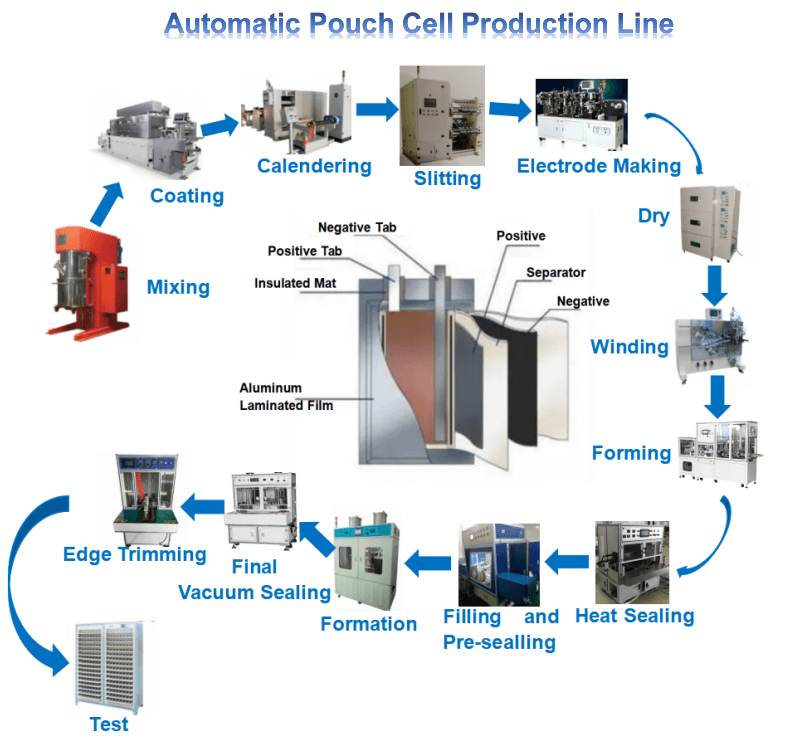

Vertical Board Seam Coater Lithium Battery Pole Coating For Pouch Cell Production

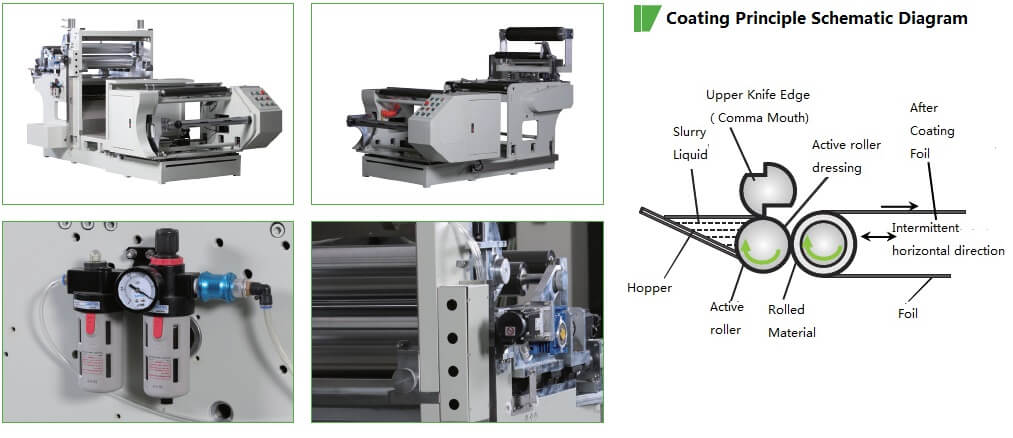

Vertical plate gap coating machine

|

No. |

Project |

Technical Parameters |

|

1 |

Process adaptability |

Lithium battery pole piece coating |

|

2 |

Coating method |

Continuous coating / gap coating |

|

3 |

Rewinding volume configuration |

Single-axis/two-axis manual roll change, automatic roll change |

|

4 |

Heating method |

Electric heating / steam heating / oil heating |

|

5 |

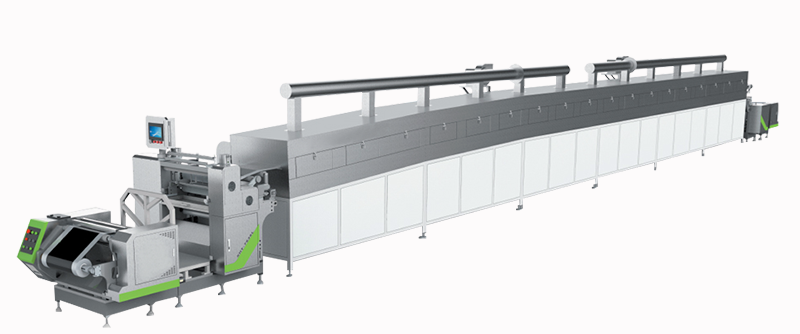

Oven configuration |

Active over roller + suspension oven, length optional |

|

6 |

Mechanical speed |

Coating speed +10% |

|

7 |

Coating speed |

1~15m/min (depending on the model) |

|

8 |

Coating width |

500mm,600mm,650mm |

|

9 |

Coating thickness |

50um |

|

10 |

Thickness accuracy |

±0.5μm (when the coating thickness is greater than 1um) |

Advantage

1.Steel roller, rubber roller, scraper installation structure is simple, easy to maintain and maintain

2.Control system is easy to operate, the touch screen interface is simple and easy to understand

3.Having a thickness head and tail thickness adjustment, automatic knife gap adjustment closed loop tension control system applied length-measuring function (optional), and negative face of homogeneous systems, the oven temperature protection system, online defect inspection system (optional)

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Roll To Roll Electrode Coating Machine For Lithium Polymer Battery ManufacturingNext :

Temperature Humidity Test Chamber For Pouch Cell Manufacturing Quality InspectionCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported