Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-MSPayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

20 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

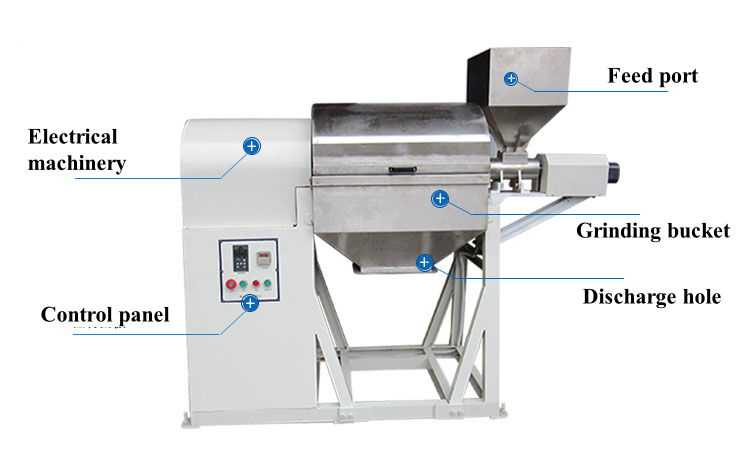

Product brief introduction

The screen ball mill is composed of a ball milling drum, a screen system, a feeding system and a material collection system. Materials can be ground and sieved simultaneously during the ball milling process. After reaching the required particle size, the materials are screened out through the screening system. The screened materials are collected by the material collection system and continuously fed through the feeding system. The screen mill is particularly suitable for materials that need to be ground to a specific particle size, such as those requiring a specific range. For instance, for materials with a mesh size of 200-300, a grinding and screening machine is very suitable. Additionally, the grinding and screening machine significantly enhances the grinding efficiency and reduces unnecessary repeated ball milling.

The principle of product crushing

When the grinding and screening machine is in operation, the grinding media and materials inside the cylinder are lifted to a certain height along with the rotation of the cylinder. Due to the effect of gravity, they fall off the cylinder wall along a parabolic trajectory. Under the impact of the grinding media and the friction and shearing effects generated by the rolling and sliding of the grinding media, the materials are crushed. The grinding and screening machine can be widely used in industries such as electronic materials, magnetic materials, biomedicine, ceramic glaze slurry, non-metallic minerals, and new materials.

Product customization

Screening and grinding machines are generally custom-made according to customer requirements. The customer provides the required grinding particle size range of the screening and grinding machine, the volume of the grinding chamber, and the material of the grinding chamber.

Product picture

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Lab Scale Conical Grinder with Variable Frequency TechnologyNext :

Stainless Steel Small Resin Strength and Wear Resistance Test Grinding MachineCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported