Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-QMPayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

20 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

Product introduction

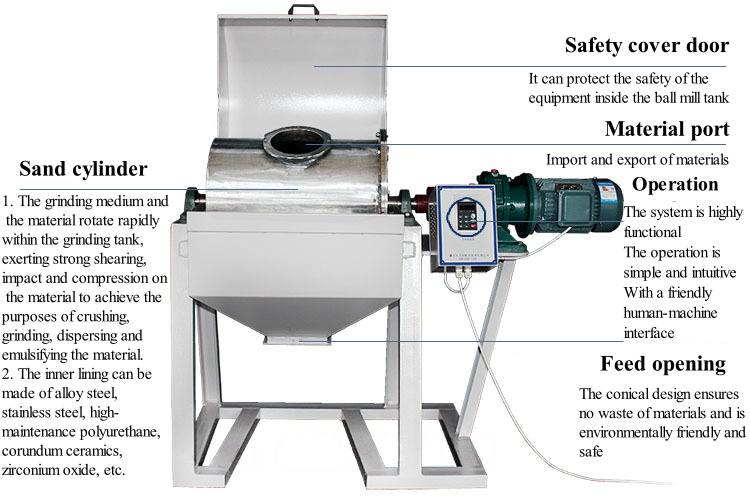

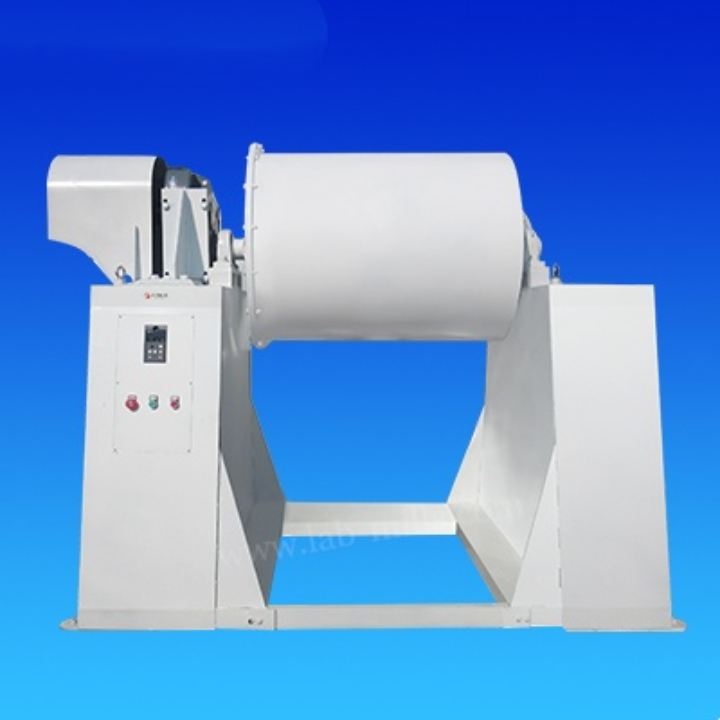

When the roll ball mill is in operation, the grinding media and materials inside the cylinder are lifted to a certain height along with the rotation of the cylinder. Due to the effect of gravity, they fall off the cylinder wall along a parabolic trajectory. The grinding media and materials roll at high speed in the grinding tank, exerting strong shearing, impact and crushing on the materials to achieve the purpose of crushing, grinding, dispersing and emulsifying the materials.

Product selection help

1. Model Description: QM - (Volume) - (A-speed type, B-normal type). For example: QM-50-A is a 50L speed-type roller ball mill.

2. Determine the machine model based on the grinding volume.

3. Select different types of ball mill tanks (or different inner linings of the ball mill tanks) and grinding balls according to the properties of the materials.

4. You can choose equipment with an automatic discharge device and dust cover.

Product feature

1. This machine operates smoothly, is energy-efficient and has low noise.

2. It can perform dry and wet grinding, handle materials of various hardness, and can be used for coarse and fine grinding or for material mixing.

3. With an automatic discharge model, the materials and balls can be automatically separated, making the discharge convenient.

4. It uses a protective outer shell, ensuring high material purity and low pollution.

5. It is resistant to wear and has high grinding efficiency.

6. Alloy steel, stainless steel, high wear-resistant polyurethane, corundum ceramics, zirconium oxide and other inner linings can be selected. The model can be chosen from 20 to 2000L according to the user's production volume.

Product parameter

|

Main Parameters of Light Roll Ball Mill |

||||||||

|

Model No. |

Volume |

Rotate Speed |

Material Capacity |

Power Supply |

Available Jars |

Feed Size |

Output Granularity |

Adjustable Mode of Rotate Speed |

|

TMAX-QM-30L |

30 |

20~60rpm |

10.5 |

0.75KW/220V |

Carbon Steel, |

≤10 |

≥300 |

Frequency adjuster |

|

TMAX-QM-50L |

50 |

20~50rpm |

17.5 |

1.5KW/220V |

≤10 |

≥300 |

||

|

TMAX-QM-100L |

100 |

20~45rpm |

35 |

2.2KW/380V |

≤20 |

≥300 |

||

|

TMAX-QM-200L |

200 |

20~40rpm |

70 |

4KW/380V |

≤20 |

≥300 |

||

|

TMAX-QM-300L |

300 |

20~38rpm |

105 |

5.5KW/380V |

≤20 |

≥300 |

||

|

TMAX-QM-500L |

500 |

20~36rpm |

175 |

7.5KW/380V |

≤20 |

≥300 |

||

|

TMAX-QM-1000L |

1000 |

20~34rpm |

350 |

11KW/380V |

≤30 |

≥300 |

||

|

TMAX-QM-2000L |

2000 |

20~34rpm |

700 |

22KW/380V |

≤30 |

≥300 |

||

Application Cases of Planetary Ball Mill

Detail picture

Product Type

Wet grinding drum ball mill

Dry grinding drum ball mill

Ceramic ball mill

Small ceramic ball mill

Large drum ball mill

Liner drum ball mill

Light ball mill

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

2 to 8 Station Laboratory Tank Mill for Fine Grinding of MaterialsNext :

Lab Scale Conical Grinder with Variable Frequency TechnologyCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported