Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-XPC/PE/PEFPayment:

L/C, T/T, Western Union, Credit Cards, PaypalMin order:

2Shipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

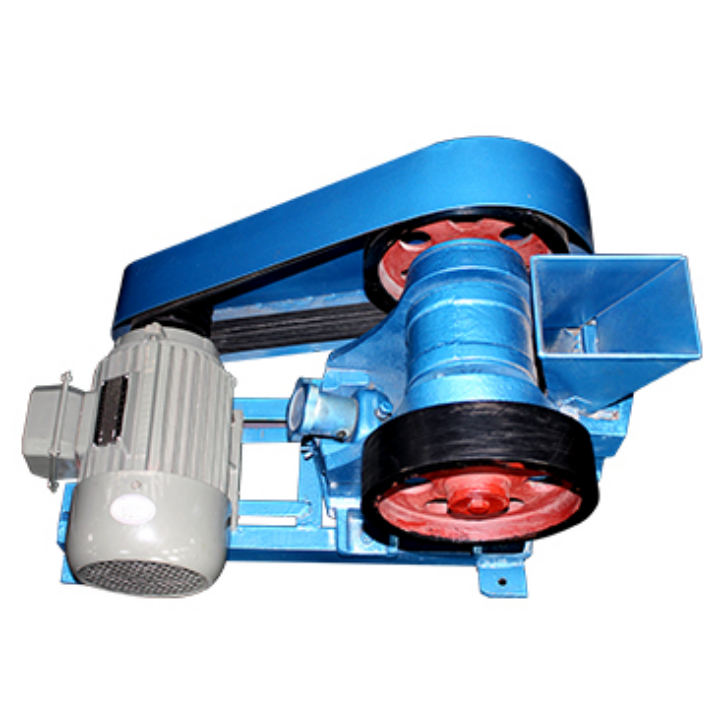

Two years limited warranty with lifetime technical supportPrimary Lab Jaw Mill Crusher Feed Size Reaching 125mm to 1200mm

Product overview

The laboratory jaw crusher (referred to as jaw crusher) is mainly used for medium-sized particle size crushing of various ores and large pieces of materials. It can crush materials with a compressive strength of no more than 320 Mpa. It is divided into coarse crushing and fine crushing. The TMAX-PE series jaw crushers have a complete range of specifications. The feed particle size is 125mm to 1200mm, and it is a primary crushing equipment for powder. This equipment is mainly used for the coarse, medium, and fine crushing of various ores such as limestone, calcium carbide, calcium carbide slag, shale, basalt, river pebbles, and bluestone. It has excellent performance in cement plants, sand and gravel plants, stone material plants, desulfurization plants of thermal power plants, calcium carbide plants, and is widely used in industries such as mining, metallurgy, chemical industry, building materials, water conservancy, transportation, etc.

Working principle

The main structure of the laboratory jaw crusher consists of the frame, eccentric shaft, large pulley, flywheel, side guard plate, elbow plate, elbow plate rear seat, adjusting screw, reset spring, fixed jaw plate and movable jaw plate, etc. Among them, the elbow plate also serves as an insurance function. This series of jaw crushers operate in a reciprocating compression type. The motor drives the belt and pulley, and through the eccentric shaft, the moving jaw moves up and down. When the moving jaw rises, the angle between the elbow plate and the moving jaw becomes larger, thereby pushing the moving jaw plate towards the fixed jaw plate. At the same time, the material is subjected to multiple crushing processes such as squeezing, rubbing and grinding. When the moving jaw descends, the angle between the elbow plate and the moving jaw becomes smaller, and the moving jaw plate, under the action of the pull rod and spring, leaves the fixed jaw plate. At this time, the already crushed materials are discharged from the lower opening of the crushing chamber. As the motor rotates continuously, the moving jaw plate of the crusher performs periodic crushing and discharging, achieving batch production.

Product features

1. The crushing ratio is approximately 15, and the particle size is uniform.

2. The pad-type discharge port adjustment device has a wide adjustment range and is reliable in operation.

3. The production efficiency is high, the energy consumption is low. Compared with the ordinary fine jaw crusher, the processing capacity of the same specification is increased by 20-35%, and the energy consumption is reduced by 15-20%.

4. The crushing chamber is deep and has no dead zone, which improves the feeding capacity and output.

5. The double-curved surface jaw plates have less wear, and under the same process conditions, the lifespan of the jaw plates can be extended by 3-4 times or more, especially for high abrasive materials.

6. The lubrication system is safe and reliable, the components are easy to replace, and the maintenance workload is small.

Product Parameter

|

Paremeters of Lab Jaw Crusher |

||||||||

|

Model No. |

Capacity (kg/h) |

Material Inlet Size(mm) |

Feeding Size(mm) |

Out-put Granularity (mm) |

Spindle Speed (rpm) |

Power (kw) |

Power Supply(v) |

Weight (kg) |

|

TMAX-XPC100*60 |

230-400 |

100×60 |

50 |

6-10 |

650 |

1.5 |

3-phase 380 |

100 |

|

TMAX-XPC100*100 |

200-1800 |

100×100 |

80 |

3-25 |

600 |

2.2 |

210 |

|

|

TMAX-XPC125*100 |

200-1800 |

125×100 |

80 |

5-25 |

500 |

3 |

235 |

|

|

TMAX-XPC100*150 |

200-1800 |

100×150 |

90 |

6-38 |

500 |

2.2 |

240 |

|

|

TMAX-XPC150*125 |

400-3000 |

150×125 |

100 |

6-38 |

500 |

3 |

250 |

|

|

TMAX-PE150*250 |

700-5000 |

150×250 |

120 |

10-40 |

350 |

5.5 |

500 |

|

|

TMAX-PEF60*100 |

45-550 |

60×100 |

50 |

0.1-15 |

600 |

1.5 |

145 |

|

|

TMAX-PEF100*100 |

65-850 |

100×100 |

80 |

1-25 |

650 |

2.2 |

200 |

|

|

TMAX-PEF100*125 |

300-2000 |

100×125 |

100 |

2-35 |

375 |

3 |

220 |

|

|

TMAX-PEF150*125 |

500-3000 |

150×125 |

120 |

4-45 |

375 |

3 |

245 |

|

Product picture

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Categories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported