Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Item No.:

TMAX-TMH300Payment:

L/C, T/T, Western Union, Credit Cards, PaypalMarket price:

$1880Price:

$1680Price range:

2400 - 4280/$1Product origin:

ChinaShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

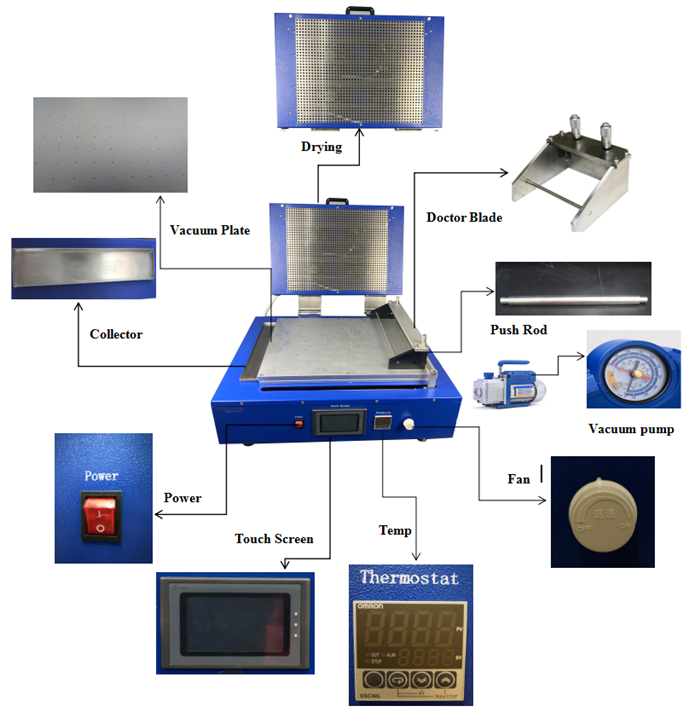

1 The TMAX-TMH300 Film coating machine with dryer is used for varies kinds of materials coating.

It is supplied with vacuum pump and heating system, having an precision heating temperature upto 200℃.

2 Thefilm coating machineis mainly used for lithium battery electrode coating for coin cell assemble and pouch cell research.

3 The film coating machineis mainly used for lithium battery electrode coating for coin cell assemble and pouch cell research.

4 Build-in oil-less vacuum pump make the machine with small volume and less noise.

5 New designed Touch Screen control make the operating more easy and simple

Specification:

|

Machine model

Automatic Film Coating Machine TMH300

Product introduction

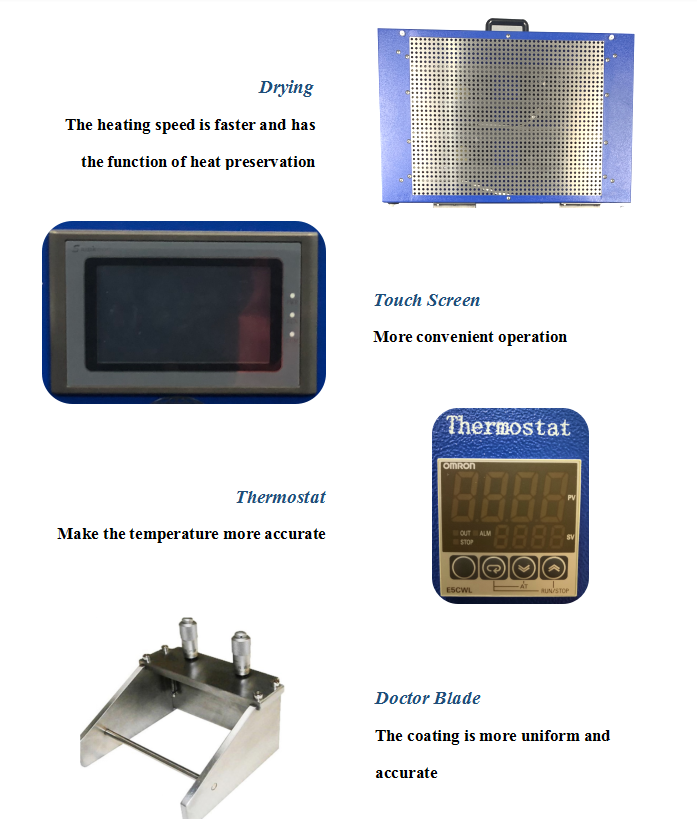

This product is widely used in various kinds of high temperature coating research, such as ceramic film, crystal film, battery material film, special nano film;The development of science and technology that can adapt to the future of film formation under high temperature conditions.

main features

1. Adopt large area uniform heating to ensure high precision uniform temperature in cavity.

2. Flat plate coating, motor driven scraper coating, coating speed is stable and adjustable.

3. Film speed adjustable, vacuum aluminum plate can be quickly placed or removed copper foil, aluminum foil, etc., built-in vacuum pump or access to external vacuum source, substrate adsorption without deformation.

4. Standard preparation of film, coating precision, coating thickness adjustable.

5. Can be used in glove box, easy to operate, small size, can save space.

6. PLC. Touch screen control parameters are easy to set.

Coating method

Flat plate coating, standard equipped with film maker, film width 250mm(can be increased), optional scraper and other metering device (manual scraping);

Coating Stroke

About 300mm, the stroke is set and adjusted in the touch screen stepless

Coating Driven

Motor driven, coating speed in the touch screen stepless setting adjustment

Dimension(L*W*H)

L550mm×W450mm×H320mm

Coating Speed

0~120mm/s(Such as iron phosphate lithium slurry)

Vacuum plate

Aluminum plate with vacuum

Warranty

One Year limited warranty with lifetime support

Size of Vacuum plate

L415mm×W300mm×H32mm

Blade thickness adjustable range

0~6mm adjustable

precision

±3 um, the optional table shows 1 um micrometer

Heating drying system

Room temperature ~ 130℃, digital display temperature controller, precision±1℃

Vacuum pump

1 built-in oil-free vacuum pump

Power

220V/50Hz

Weight

70KG

Operating procedures

1. Put the Electrode on the vacuum plate, start the power supply, open the vacuum, the electrode adsorption on the vacuum plate.

2. Place the film applicator on the electrode and add the coating slurry.

3. Open the film, the film device automatically pushes the film applicator to move, automatic film.

4. Take out the film applicator and push rod, cover with the heating cap, set the heating temperature and time, and heat and dry.

5. After drying, open the heat cover, take out the coated film electrode, film device reset complete.

Maintenance method and matters needing attention

1. Every time before work to use a soft cloth with alcohol carefully wipe the film head, the body, keep clean.

2. Film head, differentiator and other high-precision parts of the use do not collide, gently take gently, differentiator to adjust the left and right to be symmetrical and even.

3. Regularly check screws, nuts, pins and other fasteners in various parts to prevent looseness and prevent product quality accidents.

|

More models:

|

Model |

TMH250 |

TMH300 |

TMH350 |

TMH550 |

TMH800 |

TMHXXX |

|

Effective Coating Size |

100*250mm |

200*300mm |

250*350mm |

250*550mm |

250*800mm |

customized |

|

Machine Weight |

80kg |

100kg |

115kg |

130kg |

160kg |

N/A |

|

Accessories: Film Applicator |

Optional 50 up to 300 mm width micrometer film applicator is included

Or customized |

|||||

|

Optional Heating Cover Voltage and Power |

110VAC or 220VAC |

|||||

|

Traverse Speed |

0 - 120 mm/sec variable

Accuracy: 10mm/sec |

|||||

|

Vacuum Pump |

Vacuum pump is included |

|||||

|

Heating Cover |

1. Pre-installed on the top cover

2. Built in digital temperature controller with accuracy of +/-1°C

3. Suspension support helps open cover easily and safely

4. Max. Heating Temp: 200°C |

|||||

|

Compliance |

CE Certificate |

|||||

|

Warranty |

Two years limited warranty with lifetime support |

|||||

|

Operating procedures |

1. Put the Electrode on the vacuum plate, start the power supply, open the vacuum, the electrode adsorption on the vacuum plate.

2. Place the film applicator on the electrode and add the coating slurry.

3. Open the film, the film device automatically pushes the film applicator

to move, automatic film.

4. Take out the film applicator and push rod, cover with the heating cap, set the heating temperature and time, and heat and dry.

5. After drying, open the heat cover, take out the coated film electrode, film device reset complete. |

|||||

|

Maintenance method and matters needing attention |

1. Every time before work to use a soft cloth with alcohol carefully wipe the film head, the body, keep clean.

2. Film head, differentiator and other high-precision parts of the use do not collide, gently take gently, differentiator to adjust the left and right to be symmetrical and even.

3. Regularly check screws, nuts, pins and other fasteners in various parts to prevent looseness and prevent product quality accidents. |

|||||

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Roll To Roll Hot Roller Press Machine for Battery Electrode CalendarNext :

Hydraulic Manual Coin Cell Crimper for CR2032 2025 2016 Button Cell AssemblyCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported