Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-SD900CPayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

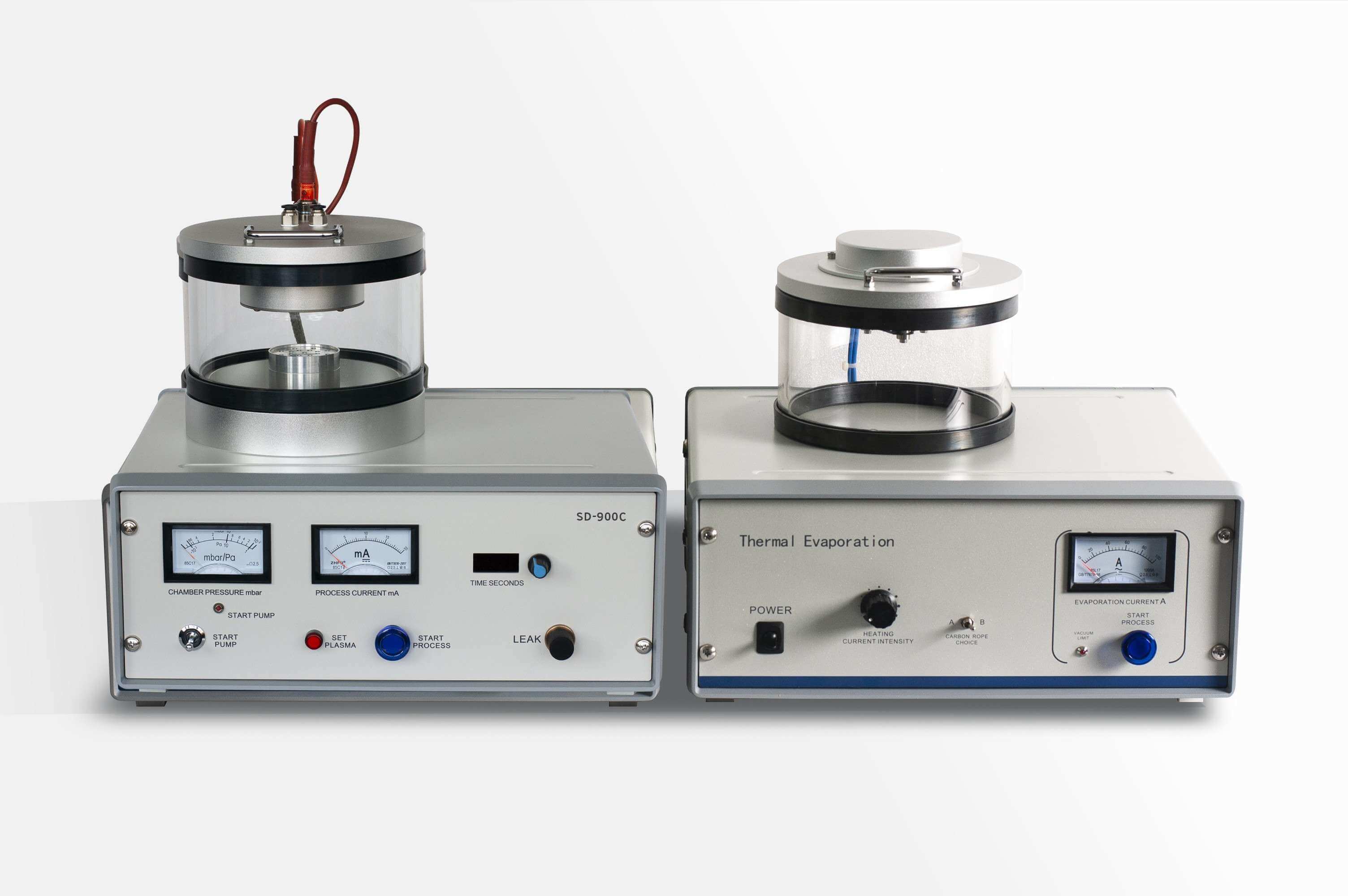

5 DaysLab Magnetron Carbon Sputtering Coating Thermal Evaporating Coater for Heat-sensitive SEM Sample Preparation

Introduction

Magnetron Ion Sputtering Unit &Thermal Evaporation Carbon Coater is ideal and designed for lab SEM sample preparation. SD900C Model (Magnetron Ion Sputtering Unit) is widely used to coat non-conductive or heat-sensitive SEM samples with Au for better imaging. It is also excellent for surface treatment and avoids damage to the substrate sample.

SD900C Model (Thermal Evaporation Carbon Unit) carbon coater applies a thin conductive carbon film on a sample surface. Applying this coating to a non-conductive sample is an effective preparation technique for diminishing charge-up electron artifacts for analysis in a SEM.

Working vacuum pressure can be achieved quickly when using proper vacuum pump within 5 minutes. It is user friendly and easy to operate.

Vacuum pump is included.

Chiller is optional. (for Magnetron Ion Sputtering Unit)

Parameter

|

Vacuum pump set |

(Oil required) rotary vacuum pump |

|

Rotary pumping speed |

50 Hz : 8 m³/h (2.2 L/s)/ 60 Hz : 9.6m³/h (2.6 L/s) |

|

Vacuum limit |

2Pa |

|

Max sputtering current |

100mA |

|

Max evaporation current |

100A |

|

Working pressure |

20Pa -8 Pa |

|

Vacuuming time |

<5 Min(2 Pa) |

|

Vacuum measure |

Measuring range from atmosphere to 2*10-2mbar |

|

Gas control |

Gas flow controller |

|

Chamber size |

Φ150*120mm (height) scratch resistant quartz glass |

|

Magnetron target source |

Target size φ 50*0.1mm(Au)/ target source: Au,Ag,Pt |

|

Evaporation target source |

Target material:carbon rope /target source:carbon rope |

|

Operation method |

Instruction Manual |

|

(2 units)Weight/size |

55kg/360mm length x 300mm wide x 380mm high |

|

Power supply |

AC 110V 60Hz or AC 220V 50Hz |

|

Power consumption |

<2000W |

|

Cooling method |

Air cooling(Evaporation)+water cooling (sputtering ) |

|

Warranty |

One year limited warranty with lifetime product support |

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Fully-automated Vacuum Pulsing Thermal Evaporating Carbon Coating Coater for Materials ScienceNext :

4.3-inch Full-color Touch Screen Magnetron Sputtering Machine Suitable for Various Metal TargetsCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported