Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-SD-02Payment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

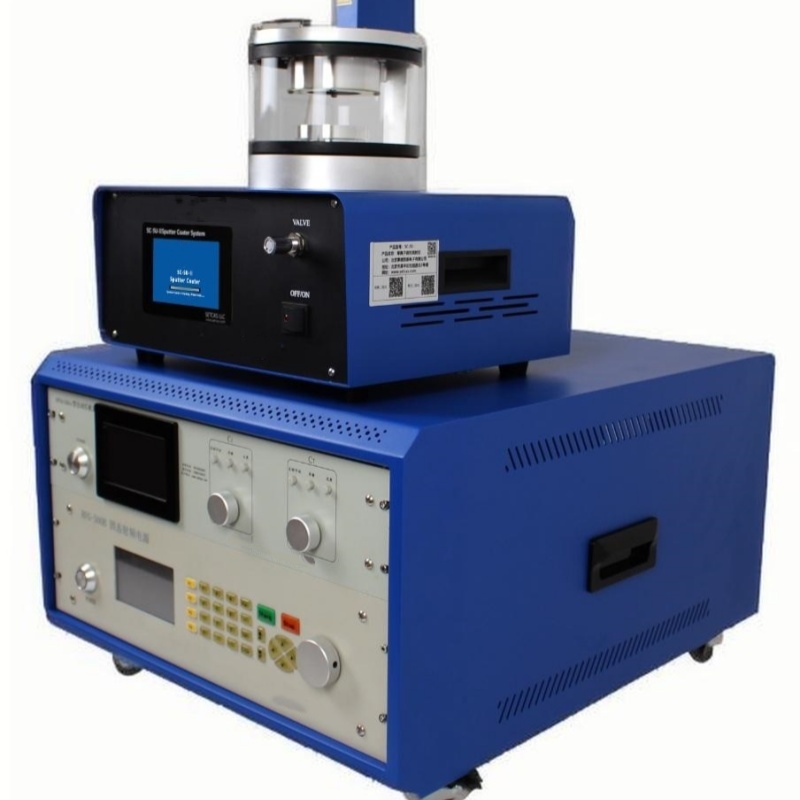

Two years limited warranty with lifetime technical supportPVD Magnetron Sputtering System for Thin Film Deposition – Ideal for Research Labs, Semiconductor Prototyping, and Optical Coating

Model: TMAX-SD-JS02-Sputtering System for Research Labs, Semiconductor Prototyping, and Optical Coating

Product Overview

The Plasma Magnetron Sputtering System (Model: TMAX-SD-JS02) is a compact, user-friendly instrument designed for high-quality thin film deposition. With a quartz chamber (150 × 120 mm) and a maximum sputtering rate of 8 nm/min, it is ideal for research and small-scale production requiring precise, uniform coatings. Compatible with inert gases (Ar, N₂) and versatile metal targets (Au, Ag, Pt, etc.), this system combines efficiency with advanced operational features.

|

Parameter |

Specification |

|

Quartz Chamber Size |

150 × 120 mm |

|

Sample Stage Size |

70 mm (diameter) |

|

Sputtering Area |

50 mm (diameter) |

|

Max. Vacuum Degree |

5 Pa |

|

Process Gases |

Argon, Nitrogen (flow rate adjustable) |

|

Max. Sputtering Rate |

8 nm/min |

|

Power Consumption |

200 W |

|

Dimensions (W×D×H) |

360 × 310 × 150 mm |

|

Operating Temperature |

0–40°C |

|

Relative Humidity |

< 85% |

|

Installation |

Horizontal desktop placement |

1. Intuitive Control & Monitoring

4.3" color touchscreen with graphical interface for real-time display of sputtering current, voltage, and vacuum levels.

2. Flexible Gas & Target Options

Adjustable inert gas flow (Ar/N₂) and support for 50 mm diameter metal targets (1–2 mm thickness), enabling quick material swaps and process reproducibility.

3. Modular & User-Centric Design

·Split-type quartz chamber for easy maintenance.

·Height-adjustable sample stage (±20 mm) with rotational alignment.

·Auto-venting post-sputtering simplifies sample handling.

4. Compact & Reliable

·Space-saving footprint with multi-layered software protections for extended durability.

5. Uniform Film Quality

·Dense, homogeneous coatings compatible with noble and transition metals (Au, Ag, Pt, etc.).

· Research Labs: Thin film studies, surface engineering, and material science.

· Semiconductor Prototyping: Deposition of conductive/metallic layers.

· Optics & Electronics: Functional coatings for sensors or display components.

Note: Optimized for small substrates (≤50 mm) and low-to-medium throughput requirements.

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

SEM Low-Temperature Mini Magnetron Sputtering System EquipmentNext :

RF Magnetron Sputtering System for Metals & Non-Metals: Insulators, Semiconductors, Carbon-Based Thin Film DepositionCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported