Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-BY-JS08Payment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

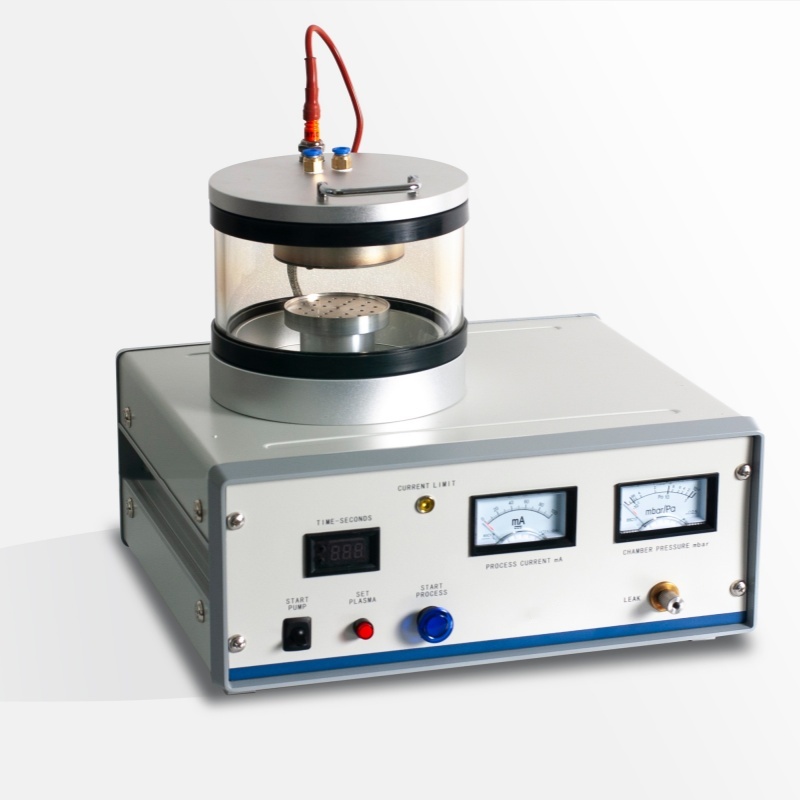

Two years limited warranty with lifetime technical supportSEM Low-Temperature Mini Conductive Magnetron Sputtering System

Glovebox-Compatible SEM Sample Coater for Beam-Sensitive Materials

1. System Overview

✔ Non-conductive sample coating (Au/Ag/Pt) for SEM imaging

Parameter

Specification

Ultimate Vacuum

4×10⁻² mbar

Base Vacuum

1 Pa

Pump Down Time

<1 minute

Vacuum Pump

Rotary Vane (2 L/s, Oil-lubricated)

Vacuum Measurement

Mechanical Gauge (Atmosphere-10⁻² mbar)

✔ Temperature-sensitive substrates (<60°C process temp)

✔ High-quality thin film deposition with minimized thermal damage

2. Core parameter

4. Glovebox-Adaptable: Optional configuration for inert atmosphere processing

Parameter

Specification

Model

Lith-BY-JS08

Sputtering Type

DC Magnetron (Physical Vapor Deposition)

Target Materials (Standard)

Au (50mmØ×0.1mm)

Optional Target Materials

Ag, Pt, Cr

Maximum Substrate Size

Ø70mm (customizable)

Chamber Material

Borosilicate Glass (160mmØ×120mmH)

System Dimensions (W×D×H)

300×360×380 mm

Weight

28 kg

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Categories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported