Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-XQM-CPayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

20 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

Product introduction

Cryogenic planetary ball mills are combined equipment of planetary ball mills and refrigeration devices. During the high-speed grinding process of most materials, due to factors such as friction or exothermic reactions, the temperature of the materials will rise, which may lead to changes in the physical and chemical properties of the materials and result in negative grinding effects. Cryogenic planetary ball mills are mainly applied in material grinding processes that require strict temperature control.

Product Applications

Cryogenic planetary ball mill is widely used in geology, minerals, metallurgy, electronics, building materials, ceramics, chemical industry, light industry, medicine, environmental protection and other departments. It is suitable for lots of production fields such as electronic ceramics, structural ceramics, magnetic materials, lithium cobalt oxide, lithium manganate, catalyst, phosphor, long afterglow phosphor, rare earth polishing powder, electronic glass, etc. Production of Powder, Fuel Cell, Zinc Oxide Varistor, Piezoelectric Ceramics, Nanomaterials, Wafer Ceramic Capacitance, MLCC, Thermistor (PTC, NTC), ZnO Varistor, Dielectric Ceramics, Alumina Ceramics, Zirconia Ceramics, Phosphor Powder, Zinc Oxide Powder, Cobalt Oxide Powder, Ni-Zn Ferrite, Mn-Zn Ferrite, etc.

Product Features

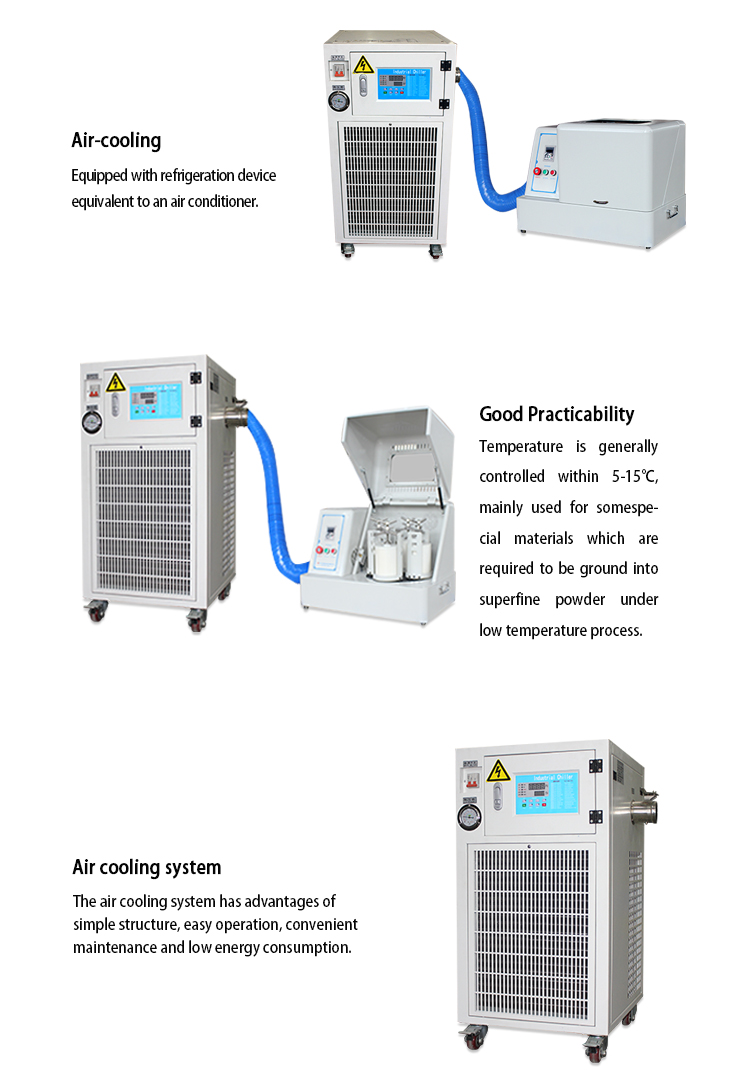

Cryogenic (Cryogenic control) planetary ball mill is a combination of planetary mill and air-cooling device. Air-conditioning compressed refrigeration principle is applied in the air-cooling device. The heat generated by grinding can be quickly removed by air cooling gas cycle. According to the difference of ambient temperature, temperature of ball-milling space can be controlled within 5-15℃. This kind of ball mill is mainly used for ultra-fine grinding under material requirements of Cryogenic technology. The air-cooling device has advantages of simple structure, convenient operation, convenient maintenance and lower energy consumption.

1. Suitable for the materials requiring ultra-fine grinding under low temperature.

2. Simple structure.

3. Easy operation.

4. Convenient maintenance.

5. Low energy consumption.

Product Parameter

|

Drive Mode |

Gear drive |

|

Operation Mode |

Two or four mill jars can be used for each grinding |

|

Max Capacity for Materials |

Less than 1/3 of each jar volume Total max capacity: less than 1/3 of total jars volume |

|

Feed Size |

Soft and crispy materials ≤ 10mm Other hard materials ≤ 3mm |

|

Volume of the ball mill jar |

Each can is 5L-50L, with a total volume of 20L-200L |

|

Output Granularity |

Smallest granularity can be achieved to 0.1μm |

|

Rotation Speed Ratio |

1:2 |

|

Speed adjustment mode |

The brand frequency converter offers stepless speed regulation with a rotational speed accuracy of 0.2 /min |

|

Max Continuous Operating Time |

72 Hours |

|

Materials of Available Mill Jars |

304 Stainless steel, 316l stainless steel, Zirconia, Nylon, PU, |

Table 1 Technical Parameters For Cryogenic Planetary Ball Mill

|

Model No. |

Specifications |

Matchable Sizes |

Matched Quantity |

Remarks (Optional) |

|

TMAX-XQM-1(C) |

2L |

50-500ml |

4 pcs |

Matched with vacuum mill jars from 50ml to 250ml |

|

TMAX-XQM-2(C) |

4L |

250-1000ml |

4 pcs |

Matched with vacuum mill jars from 50ml to 1000ml |

|

TMAX-XQM-4(C) |

6L |

1-1.5L |

4 pcs |

Matched with vacuum mill jars from 50ml to 1000ml |

|

TMAX-XQM-6(C) |

8L |

1-2L |

4 pcs |

Matched with vacuum mill jars from 50ml to 1500ml |

|

TMAX-XQM-8(C) |

10L |

1-2.5L |

4 pcs |

Matched with vacuum mill jars from 1L to 2L |

|

TMAX-XQM-10(C) |

12L |

1-3L |

4 pcs |

Matched with vacuum mill jars from 1L to 2L |

|

TMAX-XQM-12(C) |

20L |

2-5L |

4 pcs |

Matched with vacuum mill jars from 2L to 4L |

|

TMAX-XQM-20(C) |

40L |

5-10L |

4 pcs |

Matched with vacuum 5L mill jars |

|

TMAX-XQM-40(C) |

60L |

10-15L |

4 pcs |

Matched with vacuum 10L mill jars |

|

TMAX-XQM-60(C) |

100L |

20-25L |

4 pcs |

Matched with vacuum 20L mill jars |

Table 2 Technical Parameters For Cryogenic Planetary Ball Mill

|

Model No. |

Voltage |

Power |

Rotation Speed |

Total Timing |

Alternating Run |

Noise |

|

TMAX-XQM-1(C) |

220V-50Hz |

0.75KW |

70-670 rpm |

1-9999 |

1-999 |

Less than 60db |

|

TMAX-XQM-2(C) |

220V-50Hz |

0.75KW |

70-670 rpm |

1-9999 |

1-999 |

Less than 60db |

|

TMAX-XQM-4(C) |

220V-50Hz |

0.75KW |

70-670 rpm |

1-9999 |

1-999 |

Less than 60db |

|

TMAX-XQM-6(C) |

220V-50Hz |

0.75KW |

70-670 rpm |

1-9999 |

1-999 |

Less than 60db |

|

TMAX-XQM-8(C) |

220V-50Hz |

1.5KW |

70-580 rpm |

1-9999 |

1-999 |

Less than 60db |

|

TMAX-XQM-10(C) |

220V-50Hz |

1.5KW |

70-580 rpm |

1-9999 |

1-999 |

Less than 60db |

|

TMAX-XQM-12(C) |

220V-50Hz |

1.5KW |

70-580 rpm |

1-9999 |

1-999 |

Less than 60db |

|

TMAX-XQM-20(C) |

380V-50Hz |

4.0KW |

50-430 rpm |

1-9999 |

1-999 |

Less than 65db |

|

TMAX-XQM-40(C) |

380V-50Hz |

5.5KW |

40-390 rpm |

1-9999 |

1-999 |

Less than 68db |

|

TMAX-XQM-60(C) |

380V-50Hz |

7.5KW |

40-260 rpm |

1-9999 |

1-999 |

Less than 68db |

|

TMAX-XQM-100(C) |

380V-50Hz |

11KW |

40-260 rpm |

1-9999 |

1-999 |

Less than 68db |

Table 3 Technical Parameters For Cryogenic Planetary Ball Mill

|

Model No. |

Speed Control |

Net Weight |

Net Dimensions |

|

TMAX-XQM-1(C) |

Frequency Control |

93kgs |

750*470*564mm |

|

TMAX-XQM-2(C) |

Frequency Control |

93kgs |

750*470*564mm |

|

TMAX-XQM-4(C) |

Frequency Control |

93kgs |

750*470*564mm |

|

TMAX-XQM-6(C) |

Frequency Control |

93kgs |

750*470*564mm |

|

TMAX-XQM-8(C) |

Frequency Control |

150kgs |

900*600*640mm |

|

TMAX-XQM-10(C) |

Frequency Control |

150kgs |

900*600*640mm |

|

TMAX-XQM-12(C) |

Frequency Control |

150kgs |

900*600*640mm |

|

TMAX-XQM-20(C) |

Frequency Control |

330kgs |

1200*750*920mm |

|

TMAX-XQM-40(C) |

Frequency Control |

468kgs |

1400*850*1160mm |

|

TMAX-XQM-60(C) |

Frequency Control |

900kgs |

1600*990*1250mm |

|

TMAX-XQM-100(C) |

Frequency Control |

1250kgs |

1750*1140*1330mm |

Remarks: Cryogenic planetary ball mill is combination of planetary ball mill plus air-cooling device, which can be equipped with vertical planetary ball mill, horizontal planetary ball mill, full-directional planetary ball mill.

Product detail picture

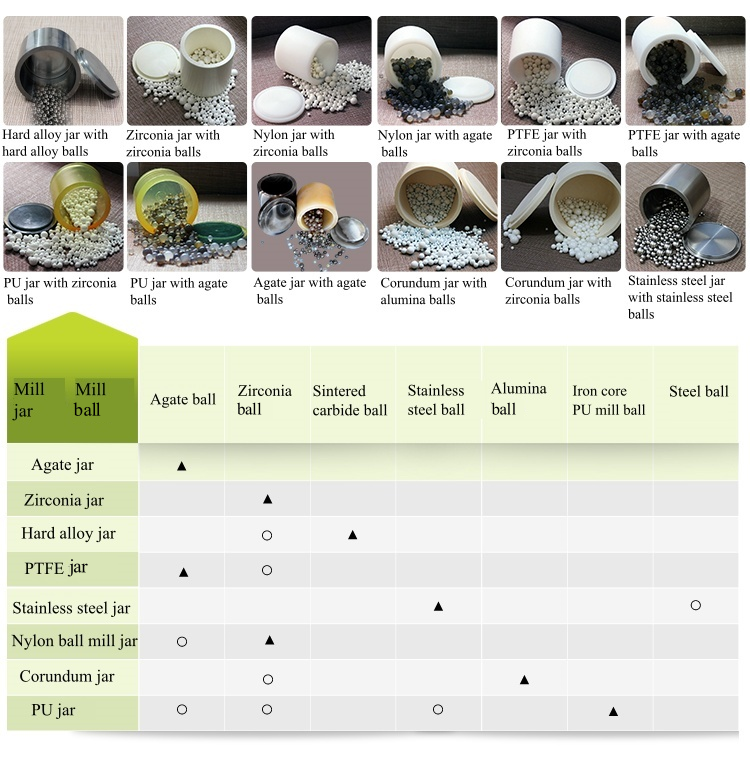

Reference for matching ball milling jars and grinding balls

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

2L to 100L Micro-Computerized Touch Screen Planetary Ball Mill with Timing and Power-Off Memory FunctionsNext :

0.2KW Small Bench-top Ultrasonic Planetary Ball Mill with 4 Working StationsCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported