Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-CSBXQM-2Payment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

20 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

Product introduction

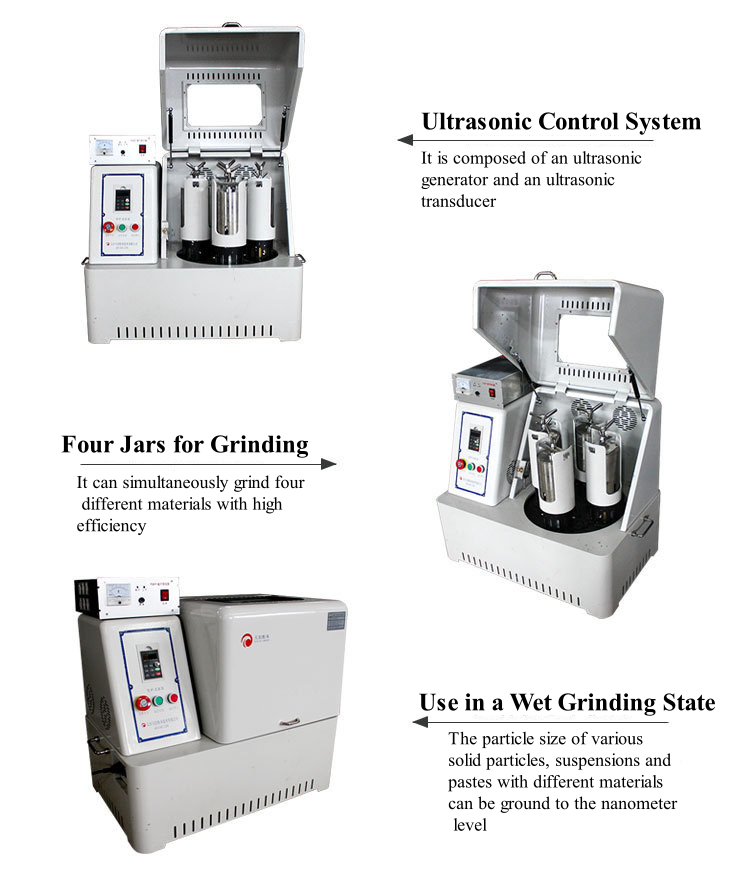

The ultrasonic planetary ball mill is a product developed based on the grinding principle of traditional planetary mechanisms. The equipment is mainly used for mixing and fine grinding materials with high particle size requirements, and where phenomena such as sedimentation at the bottom, caking, wall sticking, and agglomeration occur when using traditional ball mill equipment. Our company's ultrasonic planetary ball mill is compact in size, fully functional, highly efficient and low in noise. It is an ideal device for research institutions, universities and enterprise laboratories to obtain research samples (four samples can be obtained simultaneously in each experiment). When equipped with a vacuum ball mill jar, it can grind samples under vacuum conditions.

Product use

It is widely applied in departments such as geology, mineral resources, metallurgy, electronics, building materials, ceramics, chemical engineering, light industry, medicine, beauty, and environmental protection, for example: Electronic ceramics, structural ceramics, magnetic materials, lithium cobalt oxide, lithium manganese oxide, catalysts, phosphors, long afterglow luminescent powders, rare earth polishing powders, electronic glass powders, fuel cells, ceramic capacitors, zinc oxide varistors, piezoelectric ceramics, nanomaterials, circular ceramic capacitors, MLCC, thermistors (PTC, NTC), ZnO varistors, lightning arrester valve plates, titanium The production fields and industries of strontium acid ring varistors, ceramic filters, dielectric ceramics, piezoelectric transducers, piezoelectric transformers, chip resistors, thick film circuits, coke potentiometers, alumina ceramics, zirconia ceramics, phosphors, zinc oxide powder, cobalt oxide powder, Ni-Zn ferrites, Mn-Zn ferrites and other products.

Product working principle

Four ball milling jars are installed on a turntable. When the turntable rotates, the ball milling jars not only revolve around the main disc axis but also perform planetary self-rotation in the opposite direction around their own axes. The grinding balls and materials in the jars collide, shear and rub against each other during high-speed movement, achieving the purpose of crushing, grinding, mixing and dispersing the materials. At the same time, ultrasonic equipment (consisting of an ultrasonic generator and an ultrasonic transducer) is configured. The ultrasonic equipment is converted to the grinding tank through a conductive slip ring, enabling the inner wall of the grinding tank to continuously generate ultrasonic mechanical oscillation. This effectively solves the problems of material settling at the bottom, caking, sticking to the wall, and agglomeration in the grinding tank of traditional planetary ball mills during grinding. At present, this equipment can only be used in a wet grinding state to grind various solid particles, suspensions and pastes of different particle sizes and materials. The grinding product particle size can reach the nanometer level.

Product feature

Compared with the XQM series of the same model, the equipment has a more solid and sturdy structure and a more imposing appearance. It can achieve vibration while grinding, preventing phenomena such as material settling at the bottom, caking, sticking to the wall and agglomeration during the grinding process.

Product usage parameters and conditions

|

Power supply |

AC220V±10℅ 50HZ±2℅ |

|

Environment temperature |

0-45℃ |

|

Relative humidity |

≤80℅ |

|

The altitude does not exceed |

1000M |

|

Output power of the sound generator |

0.2KW |

|

Ultrasonic frequency |

40KHz |

|

There must be no excessive dust, acid or alkali mists, conductive, corrosive or explosive gases in the air |

|

Product detail picture

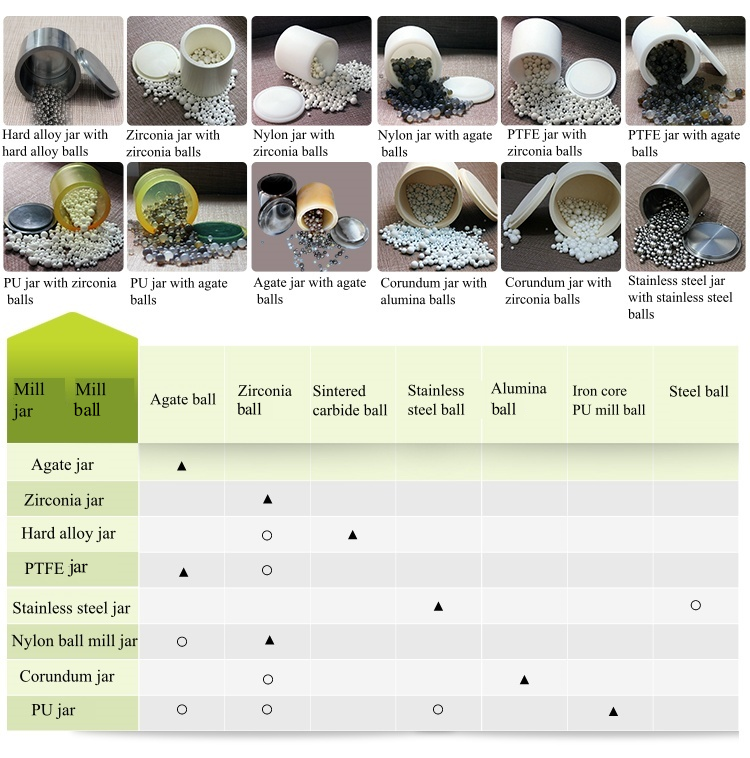

Reference for matching ball milling jars and grinding balls

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Cryogenic Planetary Ball Mill Machine for Ultra-fine Powder GrindingNext :

Large Vertical Production Type Planetary Ball Mill For Mixing and GrindingCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported