Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Item No.:

TMAX-A-017Payment:

L/C, T/T, Western Union, Credit Cards, PaypalProduct origin:

ChinaShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

Functions

Apply to lithium battery auto hot-pressing plastic soft package, cold press finalize the sharp.

Features

● Separable structure gas rose axis, forklift load/unload material strap roll material;

● Hot-pressing temperature: room temperature up to -120° C is adjustable, can be set up compensation, heating at a single point in the template control accuracy ± - 3 ° C;

● Presetting cold, hot pressing temperature and the holding time, have abnormal temperature alarm function;

● Automatic control is realized by using PLC, touch screen man-machine dialogue, convenient operation and setting;

● Top and bottom template parallelism: ±- 0.02 mm, three pieces non-carbon paper are available down out evenly when in the 1 T settle pressure, temperature;

● Hot pressing plate for copper, greatly improving the heat transfer rate, improve the uniformity of the different location of the hot platen temperature;

● Mylar circulating feeding, front-rear stability, reduce the time of manual handling;

● Mylar volume gas rose axis loading, winding speed is adjustable, gas rose axis can be separated, convenient load Mylar.

Technical Parameters(for reference):

|

ITEM |

HB-LRY300 |

HB-LRY350 |

|

Measures |

(L*W*H)2300*800*1800mm |

(L*W*H)2300*800*1800mm |

|

Weight |

About 850Kg |

About 850Kg |

|

Power |

AC220V 50HZ, 7.5KW |

AC220V 50HZ, 7.5KW |

|

Air source |

≧0.6Mpa,20L/Min |

≧0.6Mpa,20L/Min |

|

Applicable range |

L≤300mm w≤300mm |

L≤350mm w≤350mm |

|

Capacity |

Depend on cold & hot press time |

Depend on cold & hot press time |

|

Action |

≧99% |

≧99% |

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

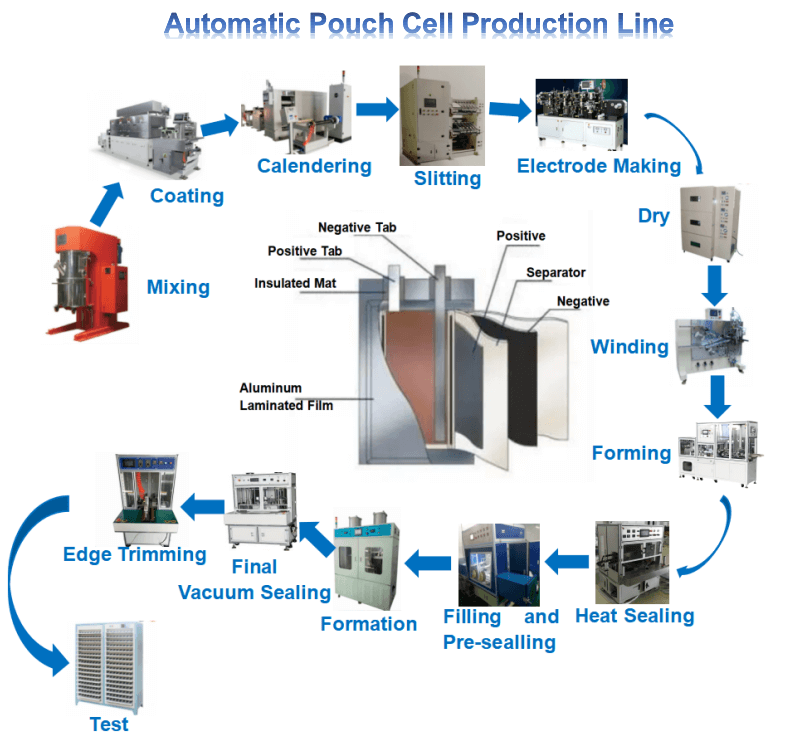

Pouch Cell Fully Automatic Assembly Production LineNext :

Semi-Auto Pouch Cell Stacking Machine Lithium Ion Battery Electrode StackerCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported