Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Item No.:

TMAX-AFA-MC400Payment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

Automatic Electrode Coating Machine Versatile Roll-To-Roll Pilot Coating System

Introduction

TMAX-AFA-MC400 is a versatile R2R coating system which can adapt various coating heads such as reverse comma blade, Doctor Blade, Slot Die and Micro Gravure and Tape Casting. A 4.5 meters long, three zone convection drying oven with independent temperature programming is implemented for efficient slurry curing. This is the most complete and universal pilot coating system that provides a broad adaptability to various coating slurries and film substrates (Cu, Al, PET, PP, PE).

For Roll to Roll Coater Service, please fill out and submit the Roll to Roll Coating Service Request Form.

Specification

|

Working Voltage |

208 - 240 VAC, 50/60 Hz, three Phase (380VAC three phase is available upon request) |

|

|

Max. Power Consumption |

30 KW ( 50A Air breaker required ) |

|

|

Compressed Air |

0.5-0.8 MPa is required (Air compressor not included.

|

|

|

Reeling/Unreeling Diameter |

|

|

|

Coating Width |

350mm Max. |

|

|

Coating Speed |

Max.5000mm/min |

|

|

Coating Heads(please select in the Product Options)

|

Doctor Blade Coating |

|

|

Reverse Comma Blade (Transfer Coating) |

|

|

|

Cast Coating |

|

|

|

Slot Die coating |

Attention: The final coating thickness is dependent on a wide range of parameters such as slurry viscosity, solid particle size, solid content, shim thickness, foil rolling speed and slurry feeding rate. Therefore, we are not able to guarantee that 1-micron level film is achievable for all kinds of slurries. For further discussion, please let us know your slurry specs and coating thickness requirement. |

|

|

Micro-Gravure Coating |

|

|

|

Convection Drying Oven |

|

|

|

Product Dimensions |

L6600mm x W1200mm x H1850mm |

|

|

Compliance |

|

|

|

Warranty |

|

|

|

Application Notes |

|

|

|

Net Weight |

12.3t |

|

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Automatic Vertical Sticking Machine For Pouch Cell Top And Side SealingNext :

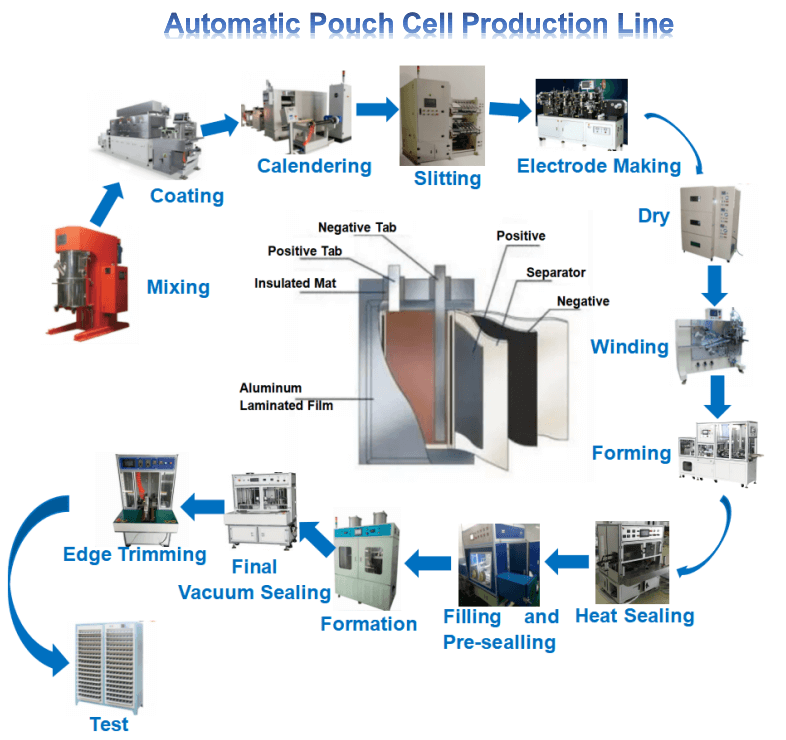

Pouch Cell Fully Automatic Assembly Production LineCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported