Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Item No.:

TMAX-ZDCKPayment:

L/C, T/T, Western Union, Credit Cards, PaypalProduct origin:

ChinaShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

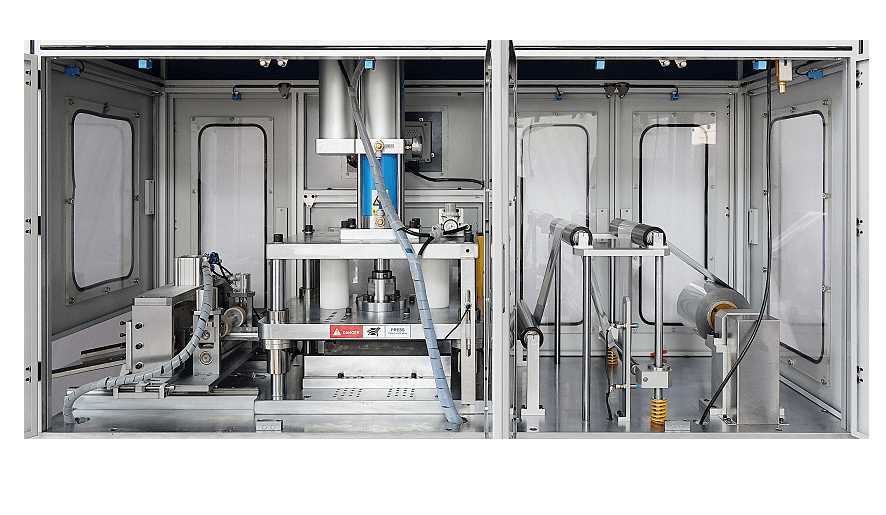

1.Introduction

This machine is mainly used for forming aluminum laminated film of pouch cell case/cup. The upper stamping adopts 10t booster cylinder and the lower stamping adopts servo motor drive. Adopt mechatronics control, PLC and servo motor to precisely control the depth of hedging shell, and use touch screen to set, adjust and operate relevant parameters. Thus makes the machine equipment operation simplification, the accuracy is higher! Equipped with safety light curtain, access switch, double button start switch, safe, convenient, efficient, long service life; customers can provide their own mold, stamping various types of battery aluminum laminated film, to meet the process requirements.

1.1Upper stamping part

1.1.1 the upper stamping is driven by servo electric cylinder, with stamping stroke of 90mm and working stroke of 10-80mm adjustable.

1.1.2 the pressing force is adjusted by inputting the pressing force through the touch screen, and the theoretical pressing force is 5T.

1.1.3 during manual operation, the maximum adjustable height of upper and lower formwork is 80mm (convenient for cleaning and replacing the formwork);

1.1.4 the stamping part is precisely positioned by four linear bearings and driven by the high-frequency wear-resistant guide rod to move the upper pressing plate repeatedly.

1.2 lower stamping part

1.2.1 it is driven by 1.5KW servo motor connected with 10:1 high-precision planetary reducer, and the connection part adopts 5mm pitch and 40mm diameter high-precision screw rod;.

1.2.2 the positioning adopts φ 28mm high-precision dense steel ball guide post, which cooperates with the guide sleeve to operate repeatedly.

1.2.3 the three die can adjust the punching depth by inputting the punching depth value on the touch screen, and the stroke is adjustable from 1 to 20 mm.

1.2.4 theoretical stamping output 2 tons.

1.3 mold part

1.3.1 three piece mold, according to customer requirements (this machine does not include mold)

1.3.2 module shell process shall be provided for mold order, and relevant parameters in the table below shall be filled in. The mold shall be made strictly according to the process.

1.4 rack part

1.4.1 the lower frame is made of square welding, and the surface is painted with computer white paint. The upper frame is composed of safety door, operation panel, door panel and aluminum profile.

1.5 circuit part

1.5.1 the circuit part is composed of PLC, touch screen, solenoid valve, intermediate relay, grating, access control switch, etc. Through touch screen, man-machine dialogue is carried out, and security protection is carried out by grating and access control.

2.Specifications

|

Rated power |

2.5KW |

|

Frame |

Surface pickling, default computer white paint (according to customer requirements) treatment The upper and lower frames are all made of aluminum profiles; The door opening of the upper rack adopts the access switch protection device to ensure safety |

|

Machine capacity |

20pcs/min(depends on the size of aluminum laminated film and the proficiency of worker) With capacity counting function |

|

Main steel members |

45#steel, Hard chrome plating |

|

Thickness of upper and lower platens |

40mm |

|

Effective working area |

400*400mm(customizable); |

|

Cutter width |

250mm |

|

Punching depth |

≤10mm(single punch) |

|

Effective stroke of lower servo stamping |

20mm |

|

Equipment utilization rate |

≥95% |

|

Product qualification rate |

≥99.5% |

|

Appearance size |

1920mm(L)*700mm(W)*2000mm(H) |

|

Total weight of equipment |

1000KG |

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

430L Large Capacity Vacuum Drying Oven With Three Separate ControllerNext :

Roll To Roll Electrode Coating Machine For Lithium Polymer Battery ManufacturingCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported