Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-WXQMPayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

20 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

Product introduction

The light horizontal planetary ball mill is symmetrically equipped with four horizontally installed ball milling jars on a vertical planetary disc. When the ball mill jar is in planetary motion, it does not have a fixed flat bottom. During the process of grinding materials, the grinding balls inside the jar, while being subjected to the two centrifugal forces of revolution and rotation, are also affected by their own gravity, which helps to enhance the degree of disordered movement of the grinding balls and materials, and improve the grinding effect and efficiency. Since the ball mill jar does not have a fixed flat bottom when rotating, it can better solve the problem of some materials settling at the bottom. The light horizontal planetary ball mill has a simple structure and is easy to operate, making it suitable for small-batch sample experiments and research in laboratories.

Product use

Horizontal planetary ball mills are widely used in departments such as geology, mineral resources, metallurgy, electronics, building materials, ceramics, chemical engineering, light industry, medicine, and environmental protection It is applicable to electronic ceramics, structural ceramics, magnetic materials, lithium cobalt oxide, lithium manganese oxide, catalysts, phosphors, long afterglow luminescent powders, rare earth polishing powders, electronic glass powders, fuel cells, zinc oxide varistors, piezoelectric ceramics, nanomaterials, circular ceramic capacitors, MLCC, thermistors (PTC, NTC), ZnO varistors, dielectric ceramics, and alumina ceramics The production fields of zirconia ceramics, phosphors, zinc oxide powder, cobalt oxide powder, Ni-Zn ferrite, Mn-Zn ferrite and other products.

Product feature

Easy operation

Unique gear with low noise

Horizontal structure of the mill pot avoids materials sinking to the bottom

Product Parameter

|

Technical Features of Horizontal Planetary Ball Mill |

|

|

Drive Mode |

Gear drive and belt drive |

|

Operation Mode |

Two or four mill jars can be used for each grinding |

|

Maximum Loading Capacity |

Less than 1/3 of each jar volume

Total max capacity: less than 1/3 of total jars volume

|

|

Feeding Size |

Soil material≤10mm, other materials≤3mm |

|

Output Granularity |

Smallest granule reaches to 0.1 μm |

|

Rotational Speed Ratio |

1/2 |

|

Max. Continuous Operating Time |

72hours |

|

Optional Modes of Speed Control |

Frequency conveter and automatic timing control |

|

Materials of Jar |

304 Stainless steel, 316l stainless steel, Zirconia, Nylon, PU,

Alumina ceramic (corundum), PTFE, Agate, Tungsten carbide

|

|

Model No. |

Specifications |

Matchable Sizes of Mill Jars |

Matched Quantity |

Matchable Sizes of Vacuum Mill Jars(Optional) |

|

TMAX-WXQM-0.4 |

0.4L |

50ml, 100ml |

4 pcs |

50ml |

|

TMAX-WXQM-1 |

1.0L |

50ml, 100ml, 250ml |

4 pcs |

50ml. 100ml |

|

TMAX-WXQM-2 |

2.0L |

50ml-500ml |

4 pcs |

50ml, 100ml, 250ml |

|

TMAX-WXQM-4 |

4.0L |

250ml-1000ml |

4 pcs |

50ml-500ml |

|

TMAX-WXQM-6 |

6.0L |

1L-1.5L |

4 pcs |

50ml-750ml |

Table 2: Technical Parameters For Laboratory Horizontal Planetary Ball Mill

|

Model No. |

Voltage |

Power |

Rotation Speed |

Noise |

|

TMAX-WXQM-0.4 |

220V-50Hz |

0.75KW |

70-670 rpm |

Less than 58db |

|

TMAX-WXQM-1 |

220V-50Hz |

0.75KW |

70-670 rpm |

Less than 60db |

|

TMAX-WXQM-2 |

220V-50Hz |

0.75KW |

70-670 rpm |

Less than 60db |

|

TMAX-WXQM-4 |

220V-50Hz |

0.75KW |

70-670 rpm |

Less than 60db |

|

TMAX-WXQM-6 |

220V-50Hz |

0.75KW |

70-670 rpm |

Less than 60db |

Table 3: Technical Parameters For Laboratory Horizontal Planetary Ball Mill

|

Model No. |

Speed Control |

Net Weight |

Net Dimensions |

|

TMAX-WXQM-0.4 |

Frequency Control |

86kgs |

700*510*570mm |

|

TMAX-WXQM-1 |

Frequency Control |

86kgs |

700*510*570mm |

|

TMAX-WXQM-2 |

Frequency Control |

86kgs |

700*510*570mm |

|

TMAX-WXQM-4 |

Frequency Control |

86kgs |

700*510*570mm |

|

TMAX-WXQM-6 |

Frequency Control |

86kgs |

700*510*570mm |

Product picture

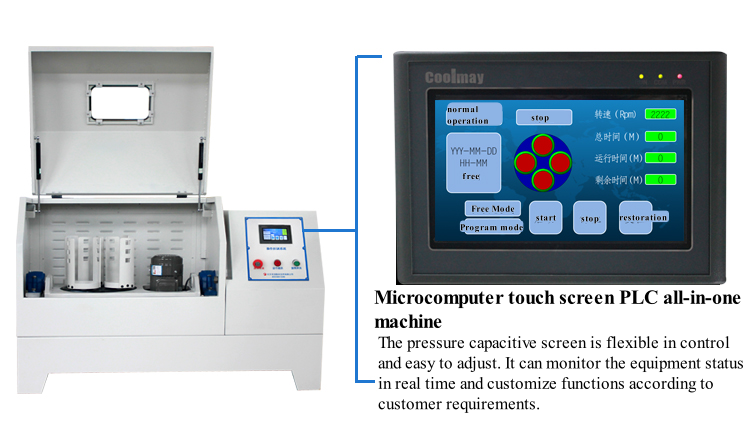

We have also launched a micro-computer touch-screen PLC all-in-one machine. Customers can choose the control panel according to their own needs.

Product detail picture

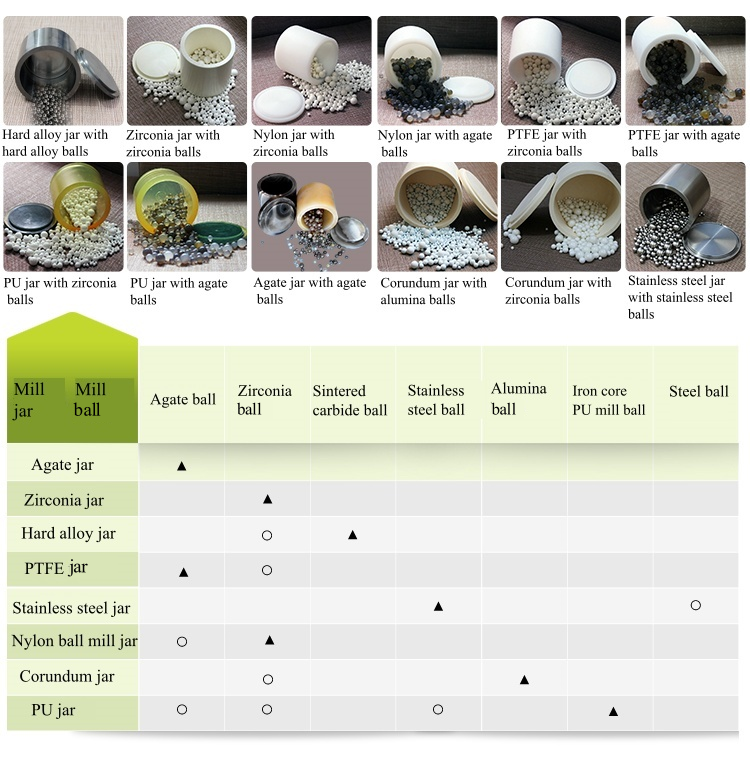

Reference for matching ball milling jars and grinding balls

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Vertical Lab Full-Directional Planetary Ball Mill with Multi-grinding JarsNext :

Heavy-duty Horizontal Planetary Ball Mill for Medium and Large Scale ProductionCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported