Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX- PTL-DZF-6120APayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical supportLaboratory 125L 400C Vacuum Drying Oven with Microcomputer Temperature Controller

A. Product brief introduction

Vacuum drying oven, also known as vacuum oven, is designed for deaerating items such as glue and silicone, for cosmetic leakage, and for drying heat-sensitive, easily decomposing and easily oxidizing substances. It can be filled with inert gas inside, especially for quick drying of items with complex components.

B. Structural features

a. Outer shell: The whole machine is thickened in design, and the outer box is made of cold-rolled steel plate electrostatically sprayed with plastic, which has strong corrosion resistance.

b. Control panel: 5-inch high-definition touch screen, showing parameters such as temperature, time, curve, scheduled on/off, standard 9999 cycle, 10-segment programming, custom mode/program-controlled mode switching.

c. Semi-automatic vacuum mode: The vacuum pumping interval time is adjustable, and the vacuum pump start time is also adjustable. (It can save the time and energy wasted by repeatedly filling the vacuum manually)

d. Door: Thickened 304 stainless steel door panel inside.

e. Door lock: With side approach handle, adjustable in tightness.

f. Sealing strips: Our company's self-molded silicone sealing strips, empty box pressure retention for more than 3 months.

g. Inner: 304 mirror-finish stainless steel inner liner, inner liner external reinforcing ribs welded.

h. Heat dissipation system: Air cooling system is adopted, and the sealing strip can work properly at high temperatures

i. i.Bulkhead: The tray is made of 304 material for good heat transfer.

j. Insulation layer: Between the box and the working chamber, 8-10CM thick ceramic fiber cotton is filled, which has good insulation function, effectively ensuring the stability and accuracy of the temperature inside the box and the impact on the usage environment.

k. Heating tubes: Stainless steel heating tubes are used.

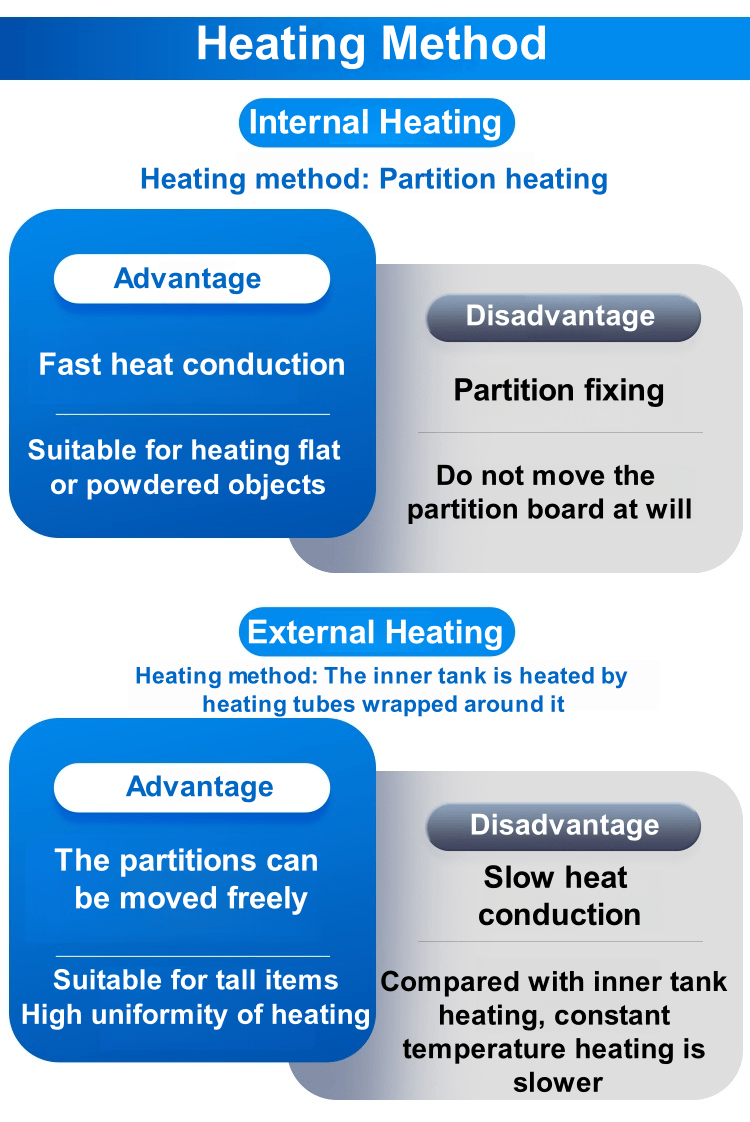

l. Heating method options: Inner heating (partition heating) with multi-point temperature correction function, allowing for individual correction of common temperature points/Outer heating (bundled heating around the inner tank).

m. Intake valve: The side is controlled by a new type of ball valve, which is easy to operate. (An inert gas intake valve can be added).

n. Solenoid valve: Replaces traditional manual ball valves to prevent vacuum pump backsuction or oil leakage due to improper operation.

o. Vacuum gauge: Use a mechanical pointer vacuum gauge.

p. Lower cabinet: Standard with Zhejiang Feiyue vacuum pump. (Other brands of vacuum pumps can also be specified).

C. Optional features

a. Embedded printer

b. RS485/232 interface

c. USB data storage (USB interface)

d. Inert gas intake valve

e. Drying oven filter tank

f. Vacuum degree is automatically controlled

g. Optional vacuum pumps of other brands

h. High water content item plan

D.Introduction to the control system

i. Personalized program design: Fixed value mode and program control mode can be switched. You can preset up to ten programmable segments and choose whether to loop the program to achieve automatic operation of temperature, speed, and time

j. It adopts a microcomputer P.I.D temperature controller with over-temperature deviation protection, over-temperature protection and touch screen display, and is equipped with a timing function.

k. Multiple timing modes:

l. The timing unit can be switched freely, in minutes and hours;

m. Timing mode: Start timing and timing after constant temperature.

n. Upgraded sound and light alarm environment scanning microcomputer chip with stable data processing function

o. Set parameters with password lock to prevent personnel from tampering with set values and other information.

p. Over-temperature alarm, over-temperature alarm, timed shutdown, power-on recovery, parameter encryption, temperature correction, speed correction and other functions.

q. With power-off recovery function: The device can automatically resume operation according to the original set program after a sudden power loss from the external power supply and the power is restored

E. Safety function

Thoughtful safety protection design for triple safety protection for people, samples, and equipment

Safety features: Sensor fault alarm, over-temperature alarm, standalone over-temperature preventer, standalone over-temperature protector, overcurrent trip protection, etc.

F. Parameter introduction

|

Product name |

400 ° C vacuum drying oven |

|

|

Product model |

DZF-6120A |

|

|

Display mode |

5-inch touch screen display |

|

|

Program/fixed value mode |

Toggable |

|

|

Power supply voltage |

380V 50HZ |

|

|

Temperature control range |

Room temperature +100 to 400 ° C (commonly recommended below 350 ° C) |

|

|

Temperature resolution |

0.1 ℃ |

|

|

Volatility |

+ / - 1 ℃ |

|

|

Vacuum gauge |

Mechanical vacuum gauge |

|

|

Reach vacuum degree |

-0.1mpa(equal to 100pa) |

|

|

Working environment temperature |

5℃ to 40℃ |

|

|

Heating method |

Internal heating (partition heating) |

Outer heating (heating with binding around the inner liner) |

|

Heating power |

2400W (1200W per partition) |

4800W |

|

Total power |

3200W |

5600W |

|

Inner tank dimensions (W*D*H) mm |

500 * 500 * 500 |

|

|

Dimensions (W*D*H) mm |

950*920*1450 (with casters) |

|

|

Pack size (W*D*H) mm |

About 1000*1000*1650 |

|

|

Equipment weight (kg) |

About 230kg |

|

|

Package weight (kg) |

About 250kg |

|

|

Cargo holder (standard) |

2 pieces (non-removable) |

2 pieces (removable) |

|

Partition spacing |

About 20cm |

|

|

Timing range |

1 to 9999 (minutes/hour switchable) |

|

|

After-sales |

One-year warranty period |

|

|

Ways to open the door |

Front side opening |

|

|

Volume |

125L |

|

|

Note: All dimensions were measured by hand and there may be an error of 1-2cm. All data were measured at (25 ° C, 70%RH). |

||

|

(The company reserves the right to change the technical parameters at any time) |

||

G. Vacuum pump parameters

|

Vacuum pump brand |

Feiyue |

|

Pumping speed m³/h |

4L/S |

|

Power supply |

Single-phase 220V |

|

Intake and exhaust port connection port DN(mm) |

KF25 or tower joint |

|

Vacuum pump power |

750W |

|

Weight of vacuum pump (kg) |

About 20kg |

|

Vacuum pump position |

Built-in vacuum pump |

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Laboratory Electric Thermostatic Blast Drying OvenNext :

Lab Electric Blast Drying Oven with Intelligent Digital Display PID Temperature ControlCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported