Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

Lith-BY-ZD02Payment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

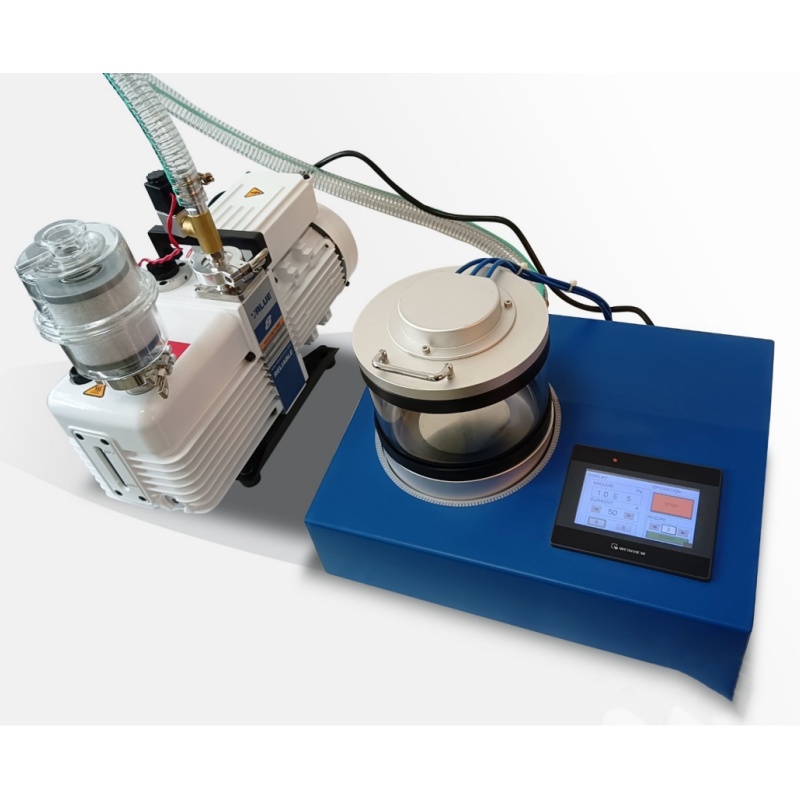

Two years limited warranty with lifetime technical supportDesktop Pulsing Thermal Evaporation Carbon Metal Deposition Coater PVD System Equipment

Model: TMAX-BY-ZD02-Pulsing Thermal Evaporation Carbon Coater

The Lith-BY-ZD02 Pulsing Thermal Evaporation Carbon Coater is an advanced deposition system designed for ultra-thin carbon film coating in SEM, TEM, and EBSD applications. Utilizing resistive heating of high-purity carbon rope, it enables precise, fast, and contamination-free carbon film deposition with adjustable parameters for optimized coating quality.

✔ Dual Deposition Modes – Supports Flash & Pulsed evaporation (0-9 pulses) for controlled, low-debris coating.

✔ Touchscreen Control – User-friendly interface for precise current/pulse adjustment.

✔ Adjustable Evaporation Current (50A-80A) – Prevents sample damage while ensuring uniform coating.

✔ Vacuum Protection System – Safeguards against low-vacuum short circuits.

✔ Compact & Efficient – Optimized for lab environments with rapid pump-down (<5 min).

|

Category |

Specification |

|

Model |

Lith-BY-ZD02 |

|

Dimensions (W×D×H) |

390mm × 310mm × 290mm |

|

Chamber Material |

Borosilicate Glass (Ø160mm × 110mm H) |

|

Sample Stage |

50mm (Diameter) |

|

Evaporation Source |

High-Purity Carbon Rope |

|

Deposition Modes |

Flash / Pulsed (0-9 pulses programmable) |

|

Max Evaporation Current |

80A |

|

Operating Vacuum |

4–6 Pa |

|

Ultimate Vacuum |

5 Pa |

|

Pump Type |

2-Stage Rotary Pump (VRD-8, 8 m³/h @50Hz) |

|

Power Supply |

220V AC, 50Hz |

|

Power Consumption |

1.6 kW |

|

Weight |

~50 kg |

· Pumping Speed:

o 50Hz: 8 m³/h (2.2 L/s)

o 60Hz: 9.6 m³/h (2.6 L/s)

· Time to Reach Vacuum: <5 minutes (to 2 Pa)

· Vacuum Measurement Range: Atmosphere to 2×10⁻² mbar

· High-Resolution SEM/TEM – Minimizes charging effects.

· EBSD Analysis – Enhances electron backscatter diffraction signals.

· X-ray Microanalysis – Provides conductive layers with minimal interference.

· Reduces Debris: Short pulses limit carbon splashing for cleaner coatings.

· Controlled Thickness: Programmable pulses (0-9) enable repeatable deposition.

· Touchscreen Interface: Intuitive control for current/pulse adjustment.

· No Process Gas Required: Simplified operation compared to sputtering systems.

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Nano PVD Thermal Evaporation Carbon Fiber Deposition System Coater For SEM/TEMNext :

Sputtering and Thermal Evaporation PVD Physical Vapor Deposition Equipment For Metal Conductive FilmCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported