Xiamen Tmax Battery Equipments Limited was set up as a manufacturer in 1995, dealing with Laboratory equipments, technology, etc. We have total manufacturing facilities of around 2, 000 square meters and more than 100 staff. Owning a group of experie-nced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy.

A dip coating machine is designed to automate and control the process of depositing thin films onto substrates through immersion and withdrawal in a coating solution. This method is widely used across various industries for producing uniform layers on different types of materials, including glass, metals, polymers, and ceramics. It's particularly useful in fields such as photovoltaics (e.g., perovskite solar cells), optics, electrochemistry, and nanotechnology.

Key Features of Dip Coating Machines

1. Programmable Control System

Allows precise control over dipping parameters such as speed, acceleration, dwell time (the duration the substrate remains submerged), and withdrawal rate. These factors significantly influence the thickness and quality of the deposited film.

2. Adjustable Dipping Profiles

Capabilities to set multiple dipping steps with varying speeds and durations within a single cycle, which can be essential for complex coating processes or multilayer coatings.

3. Substrate Holder Flexibility

Can accommodate various substrate sizes and shapes, from flat panels to cylindrical objects, depending on the configuration. Custom holders may be required for nonstandard geometries.

4. Environmental Controls

Some machines feature integrated environmental controls, allowing regulation of temperature and humidity within the chamber where the coating takes place. This is crucial for maintaining the stability of certain solutions and ensuring proper drying conditions.

5. Safety Features

Includes safety mechanisms like emergency stop buttons, interlocks, and protective covers to ensure safe operation during the dipping process.

6. Automated Solution Management

Options for automatic dispensing and recycling of coating solutions, which helps in reducing waste and maintaining consistent solution properties throughout extended coating runs.

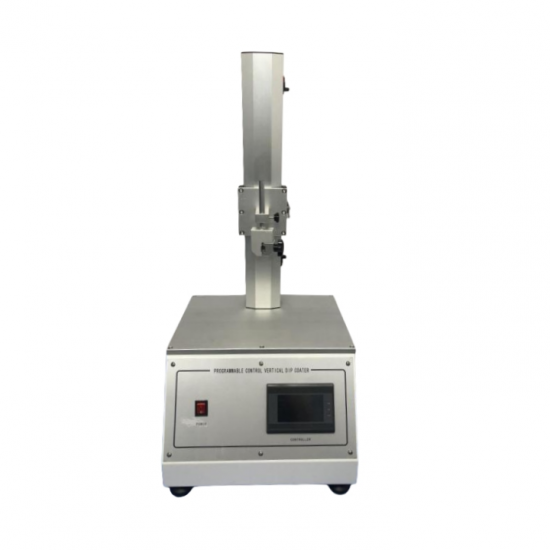

Desktop Dip Coater

Applications

Photovoltaic Devices: In the fabrication of perovskite solar cells, dip coating can be used to apply the perovskite layer or other functional layers like electron transport layers (ETL) and hole transport layers (HTL). The simplicity and costeffectiveness of this technique make it ideal for both research and production environments.

Optical Coatings: For manufacturing antireflective coatings, mirrors, lenses, and other optical components that require highquality, uniform thin films.

Electrochemical Sensors: Useful for depositing sensitive materials onto electrodes for use in electrochemical sensors and biosensors.

Catalysis Research: Applied in catalysis for coating catalysts onto supports for studying catalytic reactions.

Educational Purposes: Provides students with handson experience in thinfilm deposition techniques, making it a valuable tool in academic settings.

Considerations When Choosing a Dip Coating Machine

Application Needs: Ensure the machine meets your specific requirements regarding coating thickness, substrate size, and material compatibility.

Budget Constraints: Prices vary based on features and brand; consider what features are essential versus those that are nicetohave.

Ease of Use: Look for models with intuitive controls and clear instructions to facilitate ease of operation, especially important in educational settings.

Maintenance and Support: Consider the availability of spare parts, customer support, and maintenance services offered by the manufacturer.

Choosing the right dip coating machine involves evaluating your specific application needs, budget, and operational preferences. Whether you're conducting advanced research in renewable energy technologies, developing new optical coatings, or teaching principles of thinfilm technology, the appropriate dip coating machine can greatly enhance your capabilities and outcomes.