Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-JY300Payment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

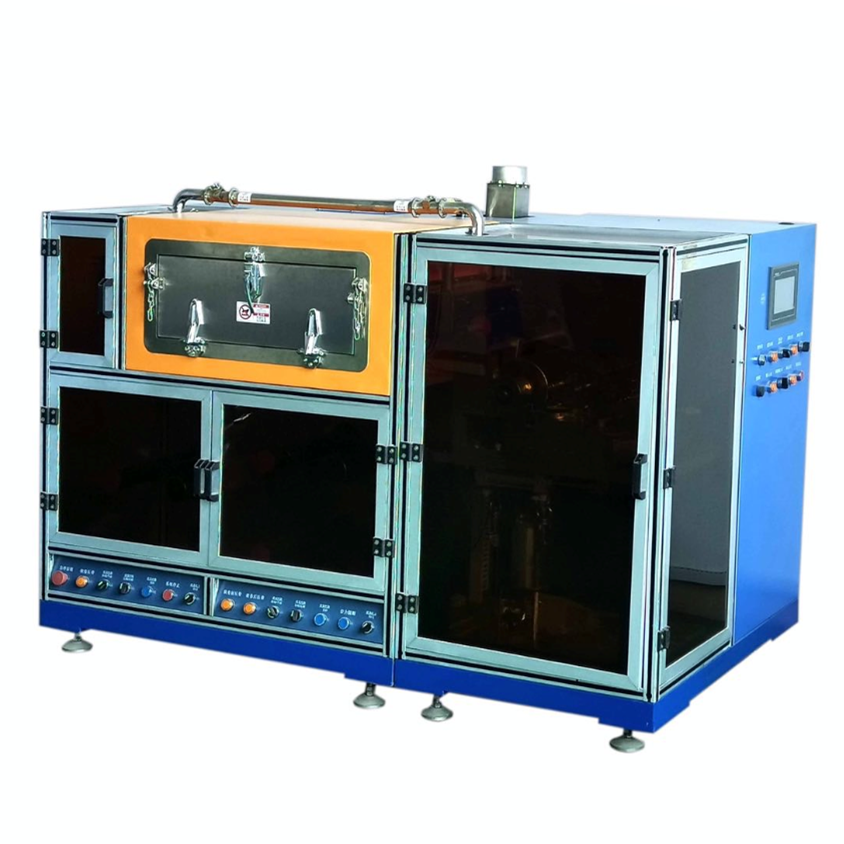

Two years limited warranty with lifetime technical supportBattery Production Slit Extrusion Slot Die Electrode Coating Machine For Continuous Coating And Intermittent Coating

Features:

* Can achieve continuous, intermittent and other shapes of coating;

*Slit extrusion coating method, high coating precision and good coating consistency;

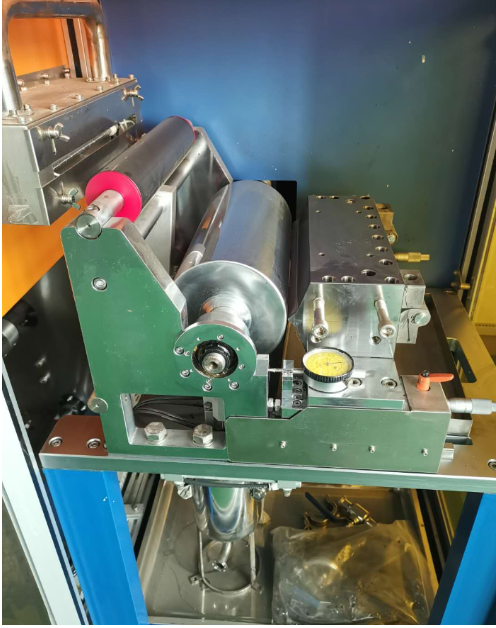

* Substrate tension control, stable belt, configuration of correcting device;

* Hot air oven, double-sided airing on the top and bottom, good drying effect;

*PLC control, touch screen operation, easy to use;

Coating equipment size and weight: size L1800*W1050*H1300mm

weight: about 600KG mounting castor foot

Installation environment requirements

1) The ambient temperature of the machine head is 25~30°C, and the rest is 10~40°C;

2) The relative humidity of the machine head is RH ≤ 35%, the negative electrode RH ≤ 98%, and the rest ≤ 98%;

Supporting facility

1) Power supply: 3PH 380V, 50HZ, voltage fluctuation range: +8%~–8%; power supply total power 10KW;

2) compressed air: after drying, filtering and voltage regulation: the outlet pressure is greater than 5.0kg/cm2;

We will still provide preuium slot die coater for you!

Function:

|

No. |

Item |

Technical parameters |

Remark |

|

1. |

Suitable for system |

Ternary, lithium iron phosphate, lithium cobalt acid, lithium manganese acid, graphite, silicon carbon and other systems of battery positive and negative plate coating process |

|

|

2. |

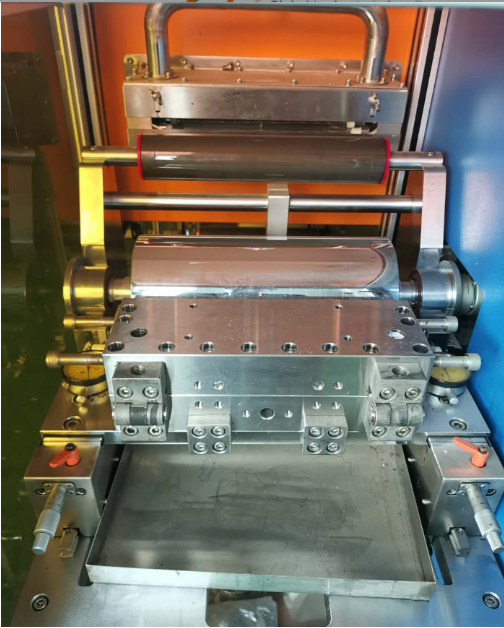

Coating method

|

Continuous coating, intermittent coating |

Slit extrusion coating method |

|

3. |

Oven section number |

1 section 0.8m oven |

|

|

4. |

Coating speed |

0 ~ 0.5 m/min |

It depends on the drying condition |

|

5. |

Operating substrate thickness |

Aluminum foil (Al) : 8 ~ 30um copper foil (Cu) : 6 ~ 30um |

|

|

6. |

Design width of roll surface |

300 mm |

|

|

7. |

Ensure the width of the coating |

Less than 240 mm |

|

|

8. |

Home roll |

Φ150mm |

|

|

9. |

Precision coating |

±1.5um |

|

|

10. |

Suitable for paste viscosity |

2000~12000 (mPas) |

|

|

11. |

Single-side dry coating thickness range |

10-250μm |

|

|

12. |

The solvent properties |

Oily solvent NMP (s.g = 1.033, p. = 204 ℃) |

|

|

Aqueous solvent H2O/NMP (s.g = 1.000, p. = 100 ℃) |

|

||

|

13. |

Suitable for solid content range |

20~85% |

|

|

14. |

Coating dimensional accuracy (mm) |

L≤±1,W≤±0.4 |

L:length direction W:width direction |

|

15. |

Front and back alignment accuracy (mm) |

L≤±1,W≤±0.4 |

Drying tunnel

|

No. |

Item |

Technical parameters |

remark |

|

1. |

Oven structure |

Double layer independent heating, up and down arrangement |

|

|

2. |

Oven length |

0.8 meters/section |

|

|

3. |

texture |

SUS304 stainless steel |

|

|

4. |

temperature control |

Divided into normal operating temperature control, overtemperature monitoring alarm protection control, and cut off the main heating power supply; Each section is controlled completely independently |

|

|

5. |

Heating Mode |

Electric heating, hot air circulation structure |

|

|

6. |

Single section oven heating power |

6KW |

|

|

7. |

Temperature in oven |

Design Max150 ℃, single section inside the oven temperature plus or minus 2.5 ℃ or less |

|

|

8. |

Blowing way |

Upper and lower air blower, upper and lower air chamber share heating body |

|

|

9. |

Structure of the wind |

The air nozzle slot USES the special mold slot |

|

|

10. |

Wind Turbine Control |

Contactor Control |

|

|

11. |

Heating control |

Solid-state relay |

|

|

12. |

The fan material |

SUS304 stainless steel |

|

|

13. |

Solvent recovery system |

Optional |

|

Winding mechanism: the function is the same as winding, as follows:

|

NO. |

Item |

Technical parameter |

Remark |

|

1. |

Rectifying marching |

Install the outlet |

|

|

2. |

Tension |

Automatic control of constant tension |

|

|

3. |

Installation structure |

The steel frame shall be installed securely |

|

|

4. |

Number of rewinding air expansion shaft |

1 set |

One-armed winding |

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Lab 300C Ultrasonic Spray Pyrolysis Coating Machine with Cast Copper Heating PlateNext :

Custom Laboratory Compact Doctor Blade Coating MachineCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported