Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-MD-SPV51Payment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

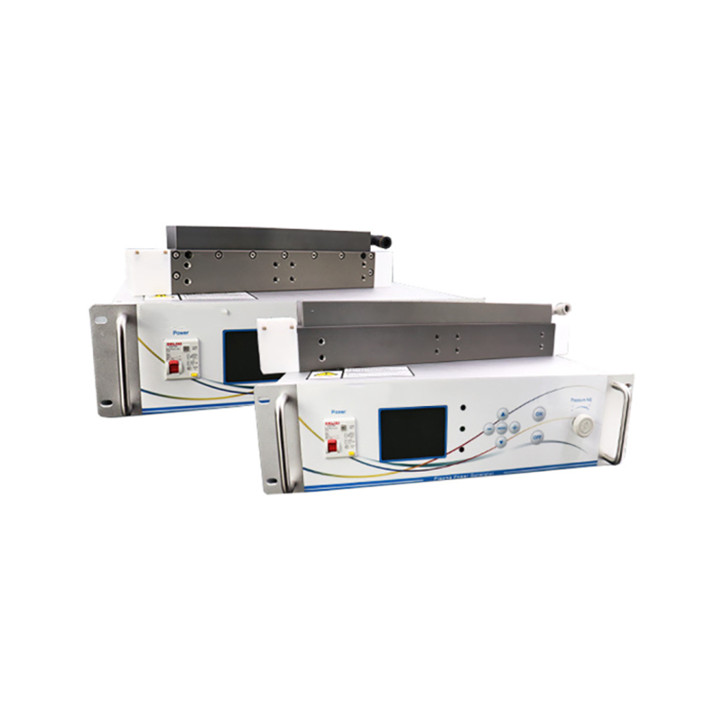

Two years limited warranty with lifetime technical supportPlasma Cleaner for Wide Material or Customized Wide Linear Plasma Processing or Assembly Line Workshop Plasma Surface Treatment

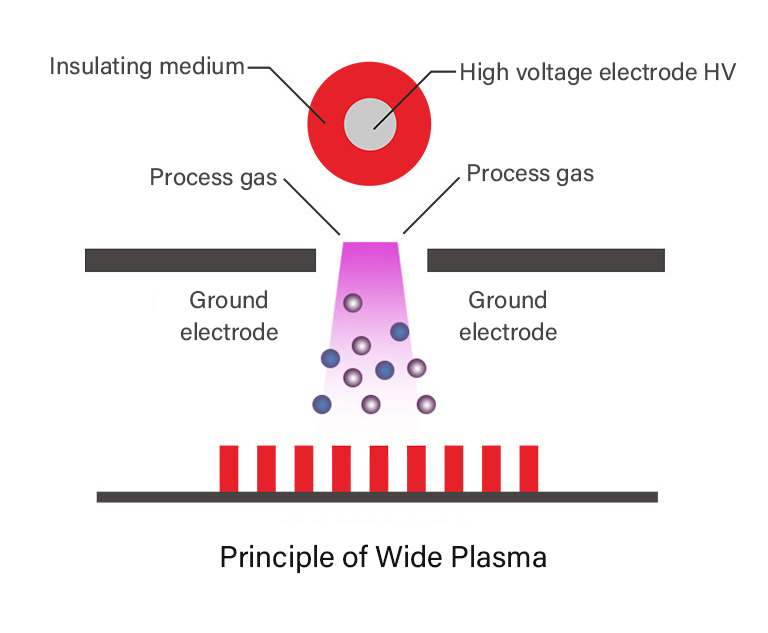

Plasma surface treatment is to apply sufficient energy to the gas to ionize it into plasma. The "active" components of plasma include: ions, electrons, atoms, active groups, etc.

Plasma treatment is to treat the surface of the sample by using the properties of these active components, so as to achieve the purpose of cleaning, modification, and etching. There are two main reactions between plasma and the surface of the material. One is chemical reaction by free radicals, and the other is physical reaction by plasma.

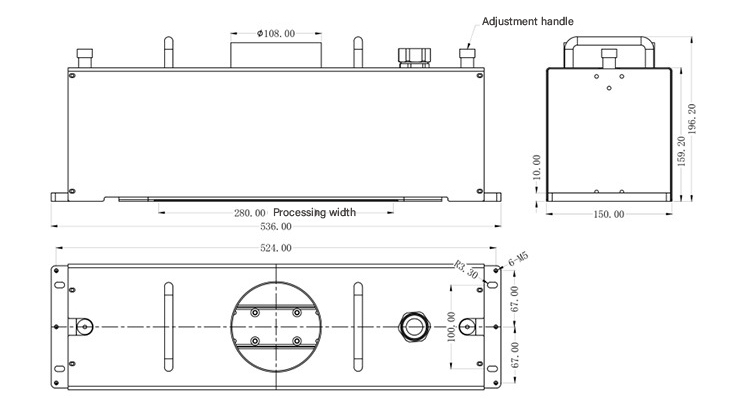

With 800mm processing width, processing time per unit area is longer, while processing area is larger, greatly improving processing efficiency.

Unique patented spray gun

Adopting a unique plasma generation structure, the normal processing temperature is less than 35℃, uniform and stable, and it is not easy to appear arc breaking, partial arc, arc starting and other phenomena.

Stable excitation power

Use customized imported/domestic radio frequency power supply, power factor≥0.95, output accuracy +1%, uniform plasma, stable processing process.

Humanized operation interface

(Can be an English panel)

The interface is simple and easy to operate and maintain, the whole process is controllable, various process parameters can be set, modified, and monitored online, and records such as gas matching can be called at any time.

Customized solution

Wide linear plasma cleaning machine can be customized gas matching and automation solutions to meet the cleaning needs of industry products.

Specification

|

Plasma power host specifications 280Z |

|

|

Chassis size |

538x480x137mm(Length x width x height) |

|

Weight |

15KG |

|

Input power |

220V, 50/60Hz, 3-wire, 20A |

|

Power frequency |

25-50KHz |

|

Plasma output power |

750-1100W adjustable |

|

Power factor |

≥0.95 |

|

Power output accuracy |

士1% |

|

way to control |

Digital control, optional local control and remote control |

|

Configuration space |

Place it in a well-ventilated place (ring mirror temperature <30°c), reserve a space of 150mm or more for heat dissipation on the |

|

Plasma power host specifications 410Z |

|

|

Chassis size |

538x480x137mm(Length x width x height) |

|

Weight |

15KG |

|

Input power |

220V,50/60Hz,3wire,20A |

|

Power frequency |

25-50KHz |

|

Plasma output power |

750-1100W adjustable |

|

Power factor |

≥0.95 |

|

Power output accuracy |

士1% |

|

way to control |

Digital control, optional local control and remote control |

|

Configuration space |

Place it in a well-ventilated place (ring mirror temperature <30°C), reserve a space of more than 150mm for heat dissipation on |

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Vacuum Plasma Cleaner or Plasma Surface Treatment or Air Plasma Cleaner for PCB and Metal SurfacesNext :

Portable Desktop Vacuum Portable-Plasma Surface Treatment CleanerCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported