A muffle box furnace, often referred to as a box furnace, is a type of industrial furnace used for various heat treatment processes, such as annealing, tempering, and sintering. It is particularly known for its enclosed design, which helps protect the material being processed from external contaminants and provides a controlled atmosphere if necessary. Here's a brief overview of a muffle box furnace:

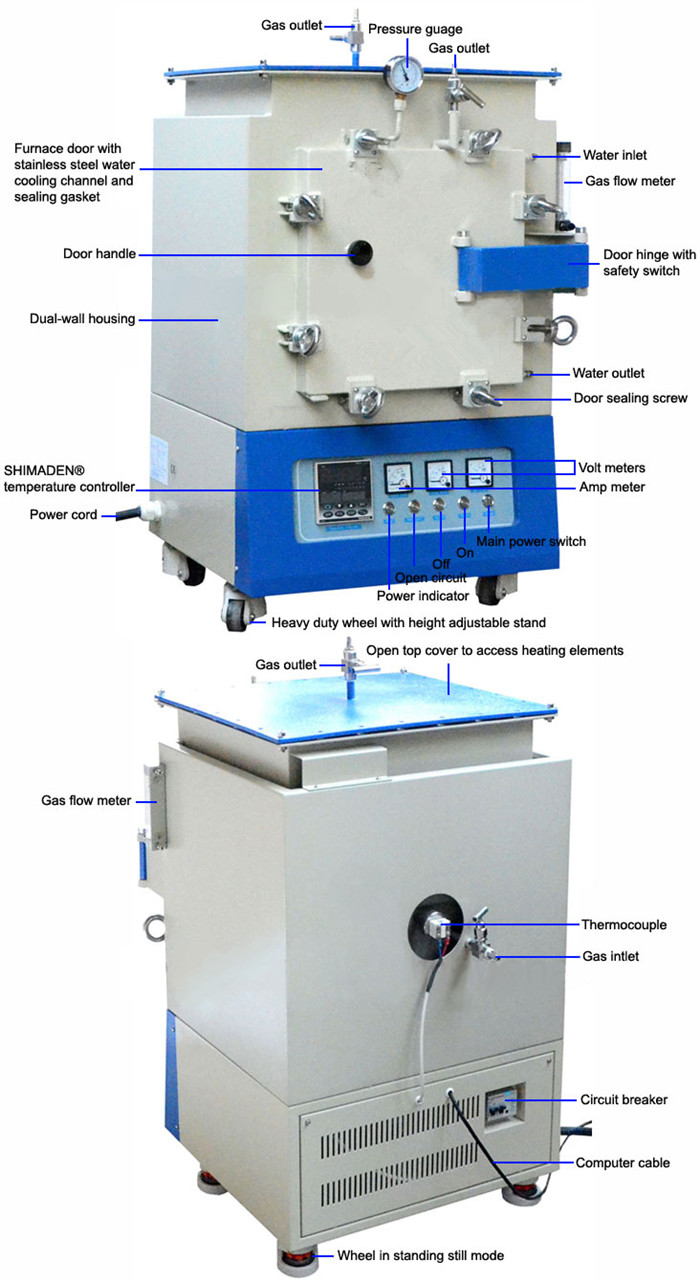

Structure and Design:

Outer Shell: The outer shell of the furnace is typically made of steel or other heat-resistant materials, providing structural integrity and insulation.

Insulation: Muffle furnaces are well-insulated to minimize heat loss and maintain a stable and uniform temperature inside the heating chamber. Common insulation materials include refractory bricks and ceramic fiber insulation.

Heating Elements: The furnace is equipped with heating elements, often made of resistance wires, embedded in refractory materials. These elements generate heat when an electric current passes through them.

Muffle or Retort: The key feature of a muffle furnace is the inner chamber called the muffle or retort. It's a separate compartment within the furnace that encloses the sample or material being heated. The muffle is typically made of a refractory material that can withstand high temperatures.

Control System: Modern muffle box furnaces are equipped with advanced control systems. These systems allow precise regulation of temperature, heating rates, and dwell times. Some furnaces also offer programmable temperature profiles for complex heat treatment processes.

Operation:

Loading: The material or sample to be heated is placed inside the muffle, ensuring it's well-protected from direct contact with the heating elements.

Temperature Setting: The operator sets the desired temperature on the furnace's control panel.

Heating: When the furnace is powered on, the heating elements begin to generate heat. The heat is transferred to the muffle, which in turn heats the material inside.

Temperature Control: The control system continuously monitors and adjusts the temperature to maintain it at the desired level. This ensures consistent and precise heat treatment.

Cooling: After the heat treatment process is complete, the furnace can be allowed to cool down gradually before opening the muffle and retrieving the treated material.

Applications:

Muffle box furnaces find applications in various industries and laboratories, including:

Metallurgy: Annealing, hardening, and tempering of metals.

Materials Science: Sintering of ceramics and powdered materials.

Dental and Jewelry: Casting, burnout, and soldering processes.

Research and Development: Various heat treatment experiments and tests.

Quality Control: Testing and analysis of materials' thermal properties.

Muffle box furnaces are valued for their ability to provide a controlled and contamination-free environment for heat treatment processes, making them essential tools in many industrial and scientific settings.