Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-ITT-SPayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

3200ML 2600ML 960ML Double Cups Vacuum Deaeration Mixer Specially Designed for Slurry Tanks

Summarize:

|

Name |

Vacuum stirring deaerator for slurry tank |

|

Equipment Model |

TMAX-ITT- 3200S,TMAX-ITT-2600S,TMAX-ITT-960S (Choose one from the three options.) |

|

Container capacity |

3200ml*2 bottles or (2600ml*2 bottles) or (960ml*2 bottles) |

|

Optimal volume of the mixture |

≤ 3200ml*2 bottles or (≤ 2600ml*2 bottles) or (≤ 960ml*2 bottles) |

|

Operating mode |

Human-computer interaction interface + button activation |

|

Orbital speed /Rotational speed |

Rotation speed: 100 - 2000 RPM. The ratio of rotation speed to revolution speed is 1.28:1. |

|

Electrical appliances (2-year warranty) |

Drive: ABB PLC: OMRON or Mitsubishi (Mitsubishi) Relay: IDEC and Quan Electrical |

|

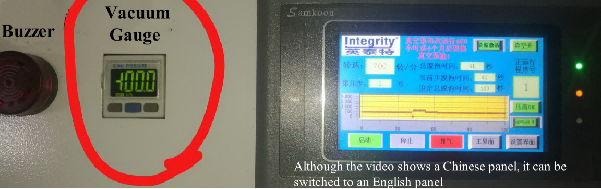

Vacuum gauge |

SMC or Panasonic vacuum gauges objectively and accurately display the vacuum level. |

|

Vacuum pump |

The German-made Small Diamon series vacuum pump is equipped with a forced lubrication pump. It provides adequate lubrication, has reliable performance, low noise, and is compatible with our company's unique 4-stage filtration system, meeting the requirements of the cleanroom. |

|

Principal axis |

S136 mirror surface steel sealing position quenching HRC 58 - 60° Mirror polishing of the sealing ring position |

|

Sealing ring |

The polymer graphene sealing ring of DuPont Company in the United States is extremely wear-resistant and can maintain long-term high vacuum. |

|

Rotary arm |

The imported aviation magnesium-aluminum alloy 7075 in the United States has an overall machining center tolerance of ±0.02, and its dimensions remain stable over the long term. It has a modular structure with high interchangeability, making maintenance and servicing very convenient. |

|

Transmission |

Using spiral bevel gears for transmission, the operation is smooth, the noise is low, and the lifespan is long. |

|

Storage program |

5 storage programs (each program can have 5 steps set) |

|

Protect |

Door cover, malfunction, overload |

|

Power supply, power, voltage |

Single-phase; ≤ 3.75KW; 220V |

|

Net weight |

220KG |

|

Outline |

L915×W730×H920mm |

|

After-sales service |

The whole machine is covered by a one-year warranty and provides lifetime maintenance! |

Dimensions: L915*W730*H920 Weight: 220KG

Vacuum Stirring Defoaming Machine :

High vacuum degree, long service life (a machine that is well maintained and serviced with regular oil replacement within 5 years will maintain a vacuum degree of no less than 5%, the vacuum degree should be maintained below -95 Kpa, the more negative the vacuum degree, the higher it is)

Easy maintenance: The entire rotating arm is made of interchangeable materials, it is easy for customers to replace parts themselves, and they can also send the parts back to our company for replacement. After replacing the parts, the effect is as good as that of a new machine.

Features of the Yingtai Te Stirring Deaerator :

Main shaft: Made of Swiss WABCO S136 mirror finish steel, after multiple heat treatments, the overall hardness reaches HRC 62 degrees. The shaft is ground as a whole, and the total runout is no more than 1 micrometer. The sealing surface is further ground to achieve a surface roughness of 0.02 um with a mirror finish effect, having an extremely low friction coefficient, and being highly self-maintainable and wear-resistant, causing minimal wear to the sealing ring, achieving an extremely long service life and high sealing performance. This is one of the reasons why many of our customers maintain a negative pressure of -98 Kpa or above even after using our product for several years.

Sealing ring: Made of German Bayer company's super wear-resistant sealing ring, with a wear resistance capacity that can reach 40 M/S linear speed. The linear speed of our equipment is only 4 M/S at 2000 revolutions. It can withstand a pressure of 20 KG/c㎡. This is one of the reasons why many of our customers maintain a negative pressure of -98 Kpa or above even after using our product for several years.

Vacuum pump: A pump with international advanced technology, modified with forced oil circulation lubrication, featuring good lubrication, low wear, and long service life. This is one of the reasons why many of our customers maintain a negative pressure of -98 Kpa or above even after using our product for several years. This oil pump has obtained a national patent (Patent Number: ZL2012.2.0084434.0)

Gear: Adopting a car spiral bevel gear structure, running smoothly with low noise, and having a long service life.

Arm: Using an integral arm, all made from imported American aviation magnesium aluminum 7075 through overall processing, ensuring product accuracy and long-term stability, with a center error no greater than ±0.02. High interchangeability, and interchangeable arm pieces of the same model can be assembled arbitrarily, making maintenance convenient.

|

ITT-List of equipment for degassing machine of the slurry tank |

|

|

Component Name |

Brand |

|

Touch screen |

Siemens or SamKoon |

|

Programmable Controller (PLC) |

Mitsubishi |

|

Motor driver |

Swiss ABB (the world's leading brand) |

|

Relay |

IDEC (Higashikawa Electric) |

|

Vacuum gauge |

Panasonic |

|

Vacuum electromagnetic valve |

304 Normally Open Type |

|

Switching power supply |

Mean Well |

|

真空泵 |

Axon (a brand under Ingersoll Rand) Double-stage pump SD-600 (flow rate > 10L/second, > 600L/minute, 36m2/hour) Maximum machine digital display relative vacuum degree: -100.2KPa |

|

螺旋伞齿轮、斜齿轮 |

Integrity Customized MC901 or Oil-impregnated Nylon |

|

转臂 |

Integrity 7075 aluminum plate complete processing |

|

搅拌杯(不提供) |

3200ML, 2600ML, 960ML |

|

旋转轴 |

Integrity ,ASSAB S136 Mirror Surface Mold Steel |

|

旋转密封圈 |

Integrity customizes Bayer polytetrafluoroethylene graphite seals |

Optional:

1. 3.2-liter slurry tank

Two 3.2-L slurry tank clamps are provided

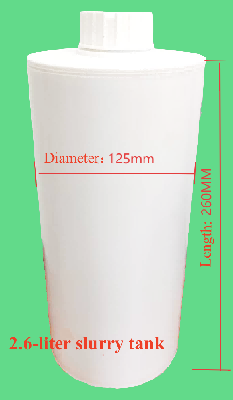

2. 2.6-liter slurry tank

Two 2.6-L slurry tank clamps are provided

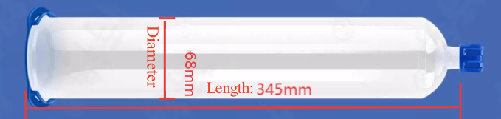

3,960ML(32-ounce) material drum

Two 960 ML material bucket clamps are provided

(Note: The above options only provide bucket clamps of matching materials. The material bucket is not included.)

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

300ml Lab Double Cup Touch Screen Adjustable Speed Planetary Gravity MixerNext :

2.6L Stepless Speed Regulation From 100 to 1500rpm Vacuum Deaerator Specifically Designed for Rubber BucketsCategories

© Copyright: 2026 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported